Global electric vehicle sales exceeded 10% market share for the first time last year. With EV sales surging, a popular topic on social media is that EV batteries are going to cause e-waste and recycling problems. To give an idea, here’s a recent, long thread thread on Reddit regarding EV battery recycling.

“I love my Tesla but someone I work with always says the following:

The big battery powering your Tesla will be bad for the planet when it fails.

I say they can recycle the parts of it and reuse the materials.”

e-Tron responded with the following:

“There are already companies setup to recycle them and it's profitable. The main problem is lack of batteries as they think it will be decades longer than expected before batteries are available in sufficient quantities.”

Another of many interesting responses came from crimxona:

Social media comments about EV battery recycling are all over the map. The reality is that industry is in position to recover over 90% of the valuable metals from EV batteries. Also, we have time, as the production of batteries for EVs and stationary storage only recently reached high volumes. It will be five-to-ten years or more before most of these early lithium-ion batteries reach the end of life.

The Promise and Challenges of Electric Vehicle Battery Recycling

Electric vehicle battery recycling is critical for waste reduction, cost reduction, national security, energy savings, and environmental protection. Metals like copper and aluminum are already widely recycled. Over 80% of all mined copper and 75% of aluminum remain in use today. These materials maintain their properties after recycling and require far less energy to process than mining new material. Given that lithium-ion batteries contain valuable metals like lithium, cobalt, and nickel, it's natural to assume they’re similarly recyclable. However, battery recycling is more complex due to the chemical nature of these materials, requiring advanced separation techniques to recover them efficiently and cost-effectively.

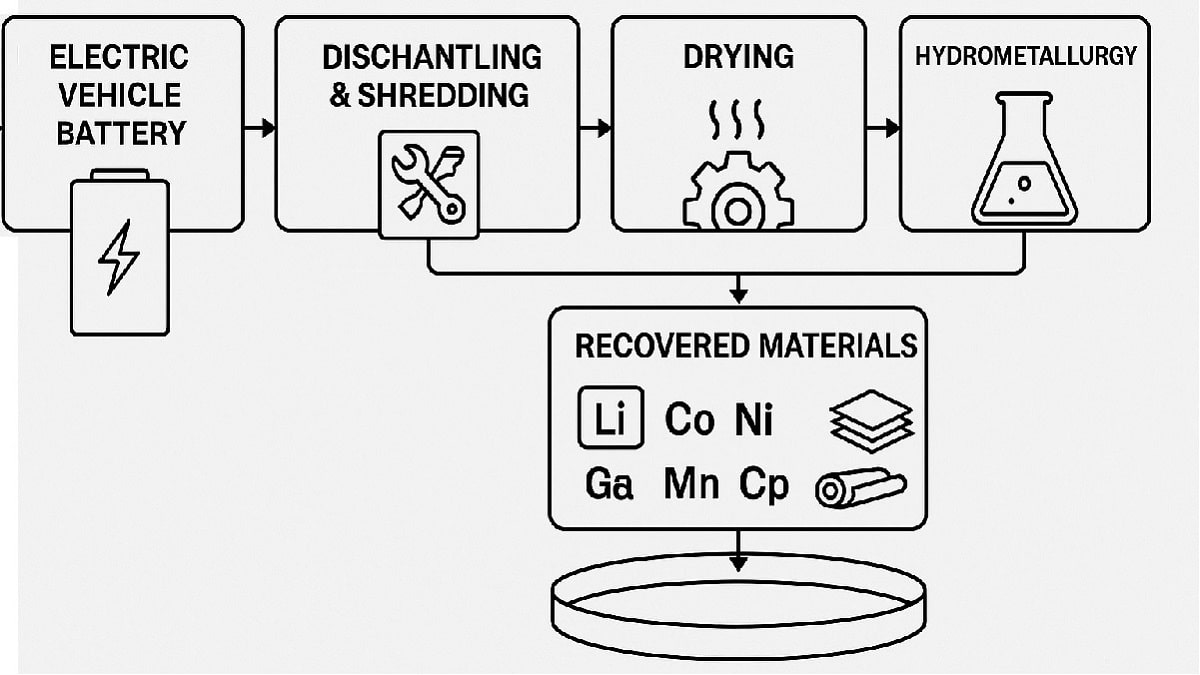

To recycle EV batteries, the process begins with discharging to safely neutralize remaining energy. Batteries are then disassembled and shredded. Two primary recycling methods exist: pyrometallurgy and hydrometallurgy. Pyrometallurgy involves high-temperature smelting to recover metals like copper, cobalt, and nickel. However, many valuable materials like lithium, aluminum, graphite, and plastics are lost during combustion. While it's scalable, established and relatively cheap, it consumes large amounts of energy and creates emissions and toxic waste if not properly managed.

Hydrometallurgy, by contrast, is a water-based chemical process. Crushed battery material, known as black mass, is dissolved using acids. Metals are then separated using various techniques like solvent extraction which binds specific metals into a solvent layer, ion exchange which uses a resin to trap desired metal ions, and pH adjustment which causes metals to precipitate or remain dissolved. Once separated, metals are recovered as solid compounds. This process can retrieve nearly all valuable metals, including lithium, and uses less energy than pyrometallurgy, but comes with more chemical waste and complexity.

Despite its advantages, hydrometallurgy has higher operational costs and slower processing times. It also requires specialized equipment and produces waste that must be carefully managed. Still, it's the preferred approach for top recyclers, with some achieving over 95% recovery rates for cobalt, nickel, lithium, and manganese. However, the economics of recycling depend heavily on the value of recovered materials. Currently, a ton of black mass contains around $4,600 of cobalt and $1,100 of nickel, while other materials offer much less value, making profitability sensitive to market prices and battery chemistry.

Test tubes containing recycled copper sulfate (blue), cobalt sulfate (brown), and nickel sulfate (green).

The rise of lithium iron phosphate (LFP) batteries poses a new economic challenge. Unlike nickel manganese cobalt (NMC) batteries, LFP batteries contain no cobalt or nickel, significantly lowering the value of black mass. While LFPs are cheaper to manufacture, they’re not easier or cheaper to recycle. That said, new technologies like solid-state batteries could help, as they use lithium metal anodes instead of graphite, which are both easier to recover and more valuable. Over time, evolving battery chemistries may alter the economic dynamics of recycling for better or worse.

As EV and energy storage battery production grows, the full scale of recycling needs won’t emerge for about a decade. Governments are stepping in to support the development of robust recycling infrastructure. In Europe, new rules coming in 2026 will require “battery passports” to track battery life cycles and enforce recycling mandates. Effective recycling reduces reliance on mined materials, potentially cutting virgin demand by 30% which improves resource security, especially for countries lacking domestic mineral reserves. These policy efforts highlight the growing recognition of battery recycling as both an environmental and strategic priority.

Companies Are Already Recycling EV Batteries at Scale

In Germany, Duesenfeld GmbH uses a multi‑step, Hydrometallurgical process optimized for high resource recovery and minimal CO₂ emissions. First, batteries are discharged, and the energy recovered is used to power a portion of the recycling plant. Battery modules are then dismantled and mechanically shredded under inert (nitrogen gas) conditions to prevent fires. This generates “black mass” containing metals, graphite, and electrolyte, which is vacuum‑dried below 80 °C to separate and condense the electrolyte. A hydrometallurgical stage then removes fluorides safely and recovers lithium, cobalt, nickel, manganese, graphite, copper, aluminum, and solvents - all as battery‑grade materials. The result is that 91% of high-value battery materials are recovered, minimal CO₂ production, and no hazardous emissions or need for gas scrubbing.

Duesenfeld GmbH has a close relationship with the Volkswagen Group. VW enlisted Duesenfeld to develop production-scale EV battery recycling process. In the United States, there are multiple players. Redwood Materials based in Nevada works with Ford, Volkswagen, BMW, Toyota, and GM. With operations in New York and Arizona, Li-Cycle has a “hub and spoke” model and supports approximately 13 major EV OEMs and 15 battery cell manufacturers. Ascend Elements based in Massachusetts works with Honda.

Please drop your thoughts in the comments below.

How long to you expect your EV battery to last before it needs to be recycled?

What questions do you have about EV battery recycling?

Chris Johnston is the author of SAE’s comprehensive book on electric vehicles, "The Arrival of The Electric Car." His coverage on Torque News focuses on electric vehicles. Chris has decades of product management experience in telematics, mobile computing, and wireless communications. Chris has a B.S. in electrical engineering from Purdue University and an MBA. He lives in Seattle. When not working, Chris enjoys restoring classic wooden boats, open water swimming, cycling and flying (as a private pilot). You can connect with Chris on LinkedIn and follow his work on X at ChrisJohnstonEV.

Image sources: AI.

Comments

Yes, they are recycled. The…

Permalink

Yes, they are recycled. The beauty of it is, the lithium can be used over and over again and it only gets more stable. EV’s are very sustainable.

With all the arguments why…

Permalink

With all the arguments why are Hydrogen cars not being pushed?

Google the Toyota Mirai for…

Permalink

In reply to With all the arguments why… by Jonathan Hai (not verified)

Google the Toyota Mirai for information on a mainstream hydrogen car on the streets in California but it’s expensive (between $50k-$100k) depending upon options. There has been hydrogen infrastructure emerging in California but there are challenges growing the supply of it vs. the initial adoption of the Mirai. Also, Chevron is investing in both traditional Hydrogen production from methane and green hydrogen production from water electrolysis using solar and wind to split off the hydrogen atoms. There is hydrogen infrastructure for industrial use of hydrogen in manufacturing but building it for consumer use in cars is more expensive challenge.

Redwood Materials are able…

Permalink

Redwood Materials are able to recover between 95-98% of a battery, and then make it into another battery! A multi-recyclable product. Gasoline, on the other hand is energy intensive to produce and then burn at a 30% efficiency rate in an ICE, wasting 70% of the product, and it’s a SINGLE USE product. How are we 16+ years into EVs and still having to explain this stuff?

"How are we 16+ years into…

Permalink

In reply to Redwood Materials are able… by Nigel Zeid (not verified)

"How are we 16+ years into EVs and still having to explain this stuff?"

Well, we *are* still explaining to some people the Earth isn't flat...

The major car companies…

Permalink

The major car companies already recycle the batteries from their old hybrids and EVs. The batteries contain high-value metals.

I can’t get away from the…

Permalink

I can’t get away from the thought of sitting in an EV means sitting on top of a tremendous amount of potential electrical energy waiting to be released, which if damaged could potentially incinerate you.

That is correct. Car…

Permalink

That is correct. Car batteries last longer than expected. Another path is rejuvenate the battery back to use. The tech is already here.

The sad matter of it all is…

Permalink

The sad matter of it all is that more people, more “progress”, leads to more damage to our environment. As humans, as intelligent as we are, we use technology to make life “better”. It seems at times that the only real answer to insure the well being of Earth, is to live like the cavemen or, possibly, like the indigenous people. Obviously, that is not realistic. Does it mean, then, that the eventual answer will be what is described in the book of Revelation in the Bible? I do not know. No one knows. We debate all of this endlessly: global warming, drill, baby, drill.

In the end, the most important thing is to believe in HIM and trust in HIM to show us the way