There is a particular tension that defines modern automotive progress. Vehicles are marketed as tougher, smarter, and more versatile than ever, yet they remain governed by the same physical laws that shaped cars decades ago.

The Tesla Cybertruck, with its stainless steel body and armored imagery, embodies this contradiction perfectly. Designed to endure abuse from the outside world, it also invites owners to explore its limits. Sometimes that exploration reveals not failure, but a misunderstanding about what a component was truly built to do.

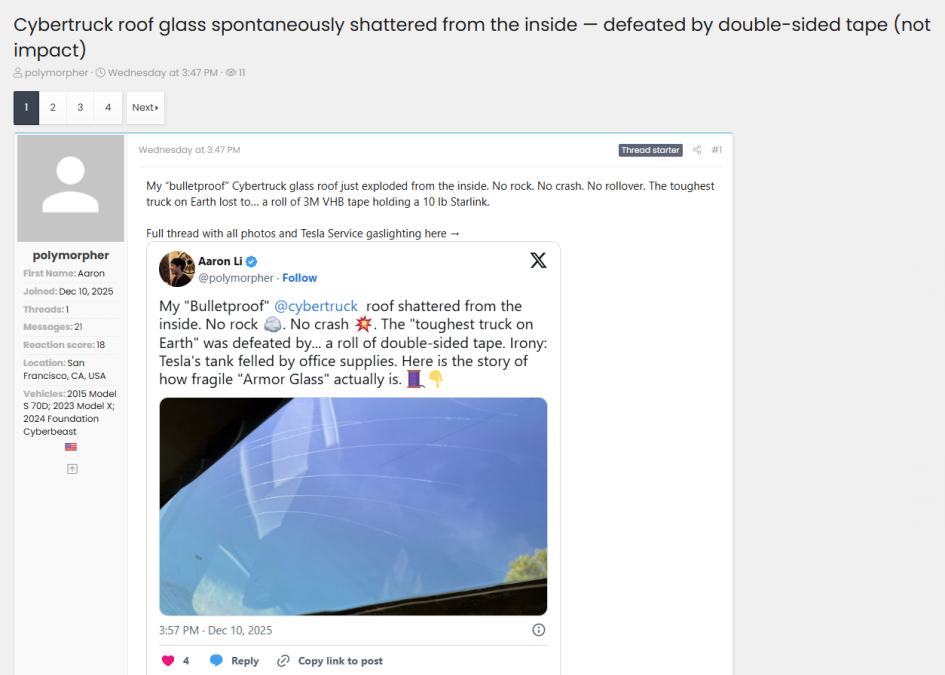

That misunderstanding came into sharp focus when a San Francisco Cybertruck owner posted photos of his shattered glass roof on the Tesla Cybertruck Forum.

“My 'bulletproof' Cybertruck glass roof just exploded from the inside. No rock. No crash. No rollover. The toughest truck on Earth lost to… a roll of 3M VHB tape holding a 10 lb Starlink.

Full thread with all photos and Tesla Service gaslighting here

Quick highlights:

Perfect concentric rings = classic tension/bending fracture, not impact (engineers will instantly recognise this pattern)

Tesla Service circled a few white flakes and called it “external impact damage” to deny warranty (those flakes are textbook spalling after the glass already snapped)

The owner’s manual has zero warnings about interior mounts or weight limits on the glass roof → a single pothole puts more stress than 10 lbs of static load

$2,500 repair quote for a roof that is supposed to survive baseballs at 70 mph and sledgehammers.

Full story + every photo in the thread above. Curious what the experts here think, manufacturing defect, bad batch, or design that can’t handle real-world use?

(Photos attached below for quick viewing).”

According to his account, the roof glass failed suddenly from the inside, without any collision, rollover, or visible impact. The only added variable was a roughly ten-pound Starlink unit mounted to the interior of the glass using industrial-grade 3M VHB tape. The resulting fracture pattern, visible in the photos, showed concentric rings typically associated with tension or bending stress rather than an external strike.

At first glance, the scenario sounds improbable. Ten pounds is trivial in automotive terms, especially on a vehicle promoted for rugged use. But glass does not think in pounds alone. Laminated automotive glass is engineered primarily to resist impacts from above, such as debris, hail, or blunt force strikes. It is not designed to serve as a mounting surface for sustained loads applied from below. When weight is rigidly bonded to glass, every pothole, vibration, and thermal cycle adds dynamic stress to a material that has very little tolerance for bending.

Tesla Cybertruck: Engineering Philosophy

- The Cybertruck’s design philosophy challenges traditional automotive manufacturing, relying on flat stainless steel panels that reduce complexity while redefining what durability looks like in a consumer vehicle.

- Steer-by-wire technology alters the driving experience by adjusting steering response based on speed, creating a learning curve that feels markedly different from hydraulic or electric systems.

- The vehicle’s architecture integrates utility directly into the body structure, with features like the covered vault and onboard power supply blurring the line between transportation and equipment.

- While its shape dominates attention, the Cybertruck’s low-mounted battery mass contributes to stability that becomes apparent during sustained highway driving.

Forum discussion quickly highlighted an important detail. Tesla and other manufacturers use multi-layer glass roofs composed of bonded sheets with different structural roles. The outer layer is optimized for strength and impact resistance, while the inner layer contributes to safety and insulation but can be more sensitive to uneven stress or heat distribution. Owners of earlier Teslas have reported cracks after tinting or thermal exposure, suggesting that the balance within these laminated systems can be delicate. In this context, a firmly bonded interior load becomes a stress concentrator rather than a harmless accessory.

Some commenters argued that mounting anything to the roof glass should have raised immediate concern. That view is reasonable, yet it collides with the way the Cybertruck has been presented to buyers. Marketing language emphasizing armor, durability, and utility naturally encourages experimentation. Compounding the issue is the absence of clear guidance in the owner’s manual regarding interior roof mounting or load limits for the glass. In engineering, what is not specified can be just as influential as what is. Silence leaves room for assumptions, and assumptions are rarely kind to glass.

The owner’s frustration deepened when Tesla Service reportedly attributed the damage to external impact after identifying small white flakes on the broken glass. He contends these flakes are consistent with spalling that occurs after a fracture, not evidence of what caused it. Regardless of where responsibility ultimately falls, the visual evidence aligns with textbook-bending failure rather than a rock strike. The resulting repair estimate of roughly $2,500 underscores how expensive the consequences of misunderstood load paths can be.

What this incident illustrates is not poor engineering, but highly specialized engineering. Strength is directional. A roof that can withstand baseballs at highway speed can still fail when subjected to continuous point loading in the wrong orientation. Standing briefly on glass distributes force across a broad area. Permanently bonding a device with high-strength adhesive creates a localized stress riser that never rests. Over time, the material responds exactly as physics predicts.

The broader lesson is simple and enduring. Advanced vehicles demand equally advanced communication between designers and owners. Clear warnings, defined limits, and explicit use cases help ensure that impressive materials are used as intended. The Cybertruck’s glass roof did not betray its mission; it fulfilled it within the boundaries of its design. When those boundaries are crossed, even unintentionally, the result can be sudden, expensive, and instructive.

Image Sources: Tesla Media Center

Noah Washington is an automotive journalist based in Atlanta, Georgia. He enjoys covering the latest news in the automotive industry and conducting reviews on the latest cars. He has been in the automotive industry since 15 years old and has been featured in prominent automotive news sites. You can reach him on X and LinkedIn for tips and to follow his automotive coverage.

Comments

How is this not just part of…

Permalink

How is this not just part of the CT ownership experience?