When I accepted Toyota’s invitation to tour their Indiana and Kentucky manufacturing plants, I had a few goals in mind. Update my aging knowledge base on American manufacturing, explore some cool technology, and learn a bit more about the popular electrified models Toyota produces. I did not expect to see four-year-olds being educated and cared for in a public school system at Toyota’s expense. Nor did I expect to see six and seven-year-olds programming and operating three different types of robots in the local first-grade Design and Innovation studio lab. I never would have imagined sharing an emotional moment with the Plant President. Yet, these surprises and more awaited me on what turned out to be a remarkable two-day tour.

Why Toyota Manufacturing in America Matters and Why Do My Impressions Matter?

America has new leadership, or perhaps new leadership for the second time, who wants to bring manufacturing and skilled labor back to the United States. This, after we allowed educators and policymakers to tell our children for two generations that it was much better to work smarter than harder, and to hint very strongly to them that if you don’t end up in a desk job after college, you’re a loser.

Read over the comments under any story about an American shift back to being a manufacturing world leader.

- “Who will do these jobs!?”

- “Why would anyone intentionally limit their child’s success by suggesting they skip college and learn a trade?”

- “Why would anyone want to work in a loud, dirty factory?”

- “Car factories in America just assemble cars from parts made overseas, so what’s the point?”

All fair questions, but sadly asked by many who seem to want to see America fail. My Toyota trip provided insight into each of these questions.

Who Can Fill Expanding American Manufacturing Jobs?

During my trip, I met some of the people who can fill the upcoming American manufacturing jobs. I didn’t get all of their names, but I remember Gunner and Neo. Both are four years old. They attend the Princeton, Indiana, pre-K program, inside the North Gibson School Corporation (Indiana calls its public school districts “corporations”). The pre-K program is a partnership with Toyota Indiana through the Toyota Driving Possibilities initiative, funded by Toyota USA Foundation. The children learn just what you’d expect in a top-notch pre-K. Colors, numbers, shapes, all that jazz. However, they also learn socialization skills, how to express feelings, and how to make and be a friend. The fully inclusive class includes students who may be nonverbal, so tools such as a communication board are available in the classroom.

We next visited the first grade. Here is where the Toyota influence seemed more apparent. There is a STEAM room (science, technology, engineering, art, and mathematics). These children are all around six. The first thing I noticed was the row of 3D printers that the children operate. During my stay, the kids showed me how to use three different robots. The most basic was a clear ball controlled via a small tablet with those rubberized bumpers to prevent it from damage. The students learn how to move the ball around a course using the electronic controls. Sounds easy, but the kids could drive circles around the uninitiated adults. Up next, a little robot car that the kids would operate using a sort of map (looking like an old-school bingo card) and some six-inch square color pads they would lay on the floor. The basic idea was to follow the program and then lay out the colored squares to see if the car would follow the map correctly. It helps kids understand how code makes machines move. Finally, a real robot. Connected to a real laptop with real programming. The kids would use the robot to load little Lego-type blocks into a bin. Six. Years. Old. This is all possible as a result of Toyota offering support to the community in which its plant was co-located.

Dr. Eric Goggins, the school Superintendent, was our enthusiastic host and tour guide. He explained the Driving Possibilities program. It’s a partnership between Toyota and the school system. Toyota didn’t just write a check. They created an integrated education system that stunned this former engineering student. Toyota has committed over $110,000,000 to the program, including disbursement from Toyota USA Foundation of approximately $6,000,000 to this particular school district and its community partners. Toyota states that it believes all children deserve an equal opportunity to access rewarding careers and goes so far as to say that the future of its company depends on it.

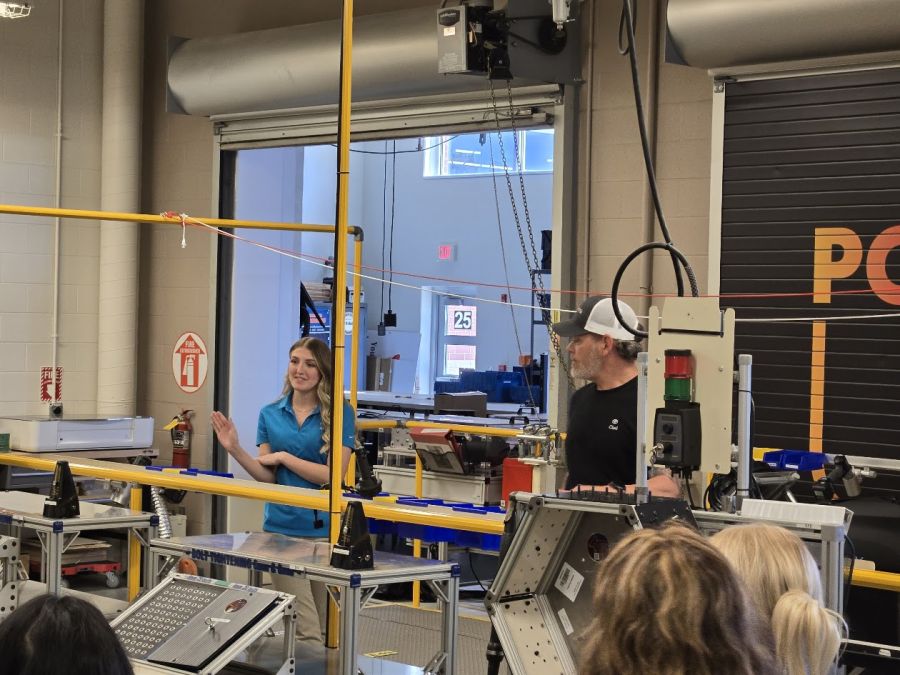

Our trip then moved on to the local high school. We visited the 4T Academy, a manufacturing learning center, which was an ideal mimic of the one used to educate new employees at the TMMI plant. Students can learn hand-eye coordination, dexterity, basic tool operations, and then move on to more advanced tools. Think of it as a vocational classroom, but spotless. What is unique about this vocational center is the section of automotive manufacturing line with two mock-up cars, on which students can learn the basics of how a vehicle is built. It even had the same andon cord “stop the line” ropes that workers pull when a vehicle is found to deviate from allowable specifications. Our host was a Toyota employee who learned to teach on the fly from his own students. His first survey of the initial class revealed that the students wanted “less PowerPoint and more hands-on.” The program’s current curriculum has been shaped in large part by the students.

The students who participate opt into this program. They begin their junior year spending approximately three hours per school day being introduced to the career of advanced manufacturing and the ins and outs of working at Toyota. During their senior year, they continue their at-school training, but also spend time with hands-on training at the Toyota plant. By the second semester of their senior year, they are training at the plant 10 hours a week, during the school day, and earning $18.00 per hour. Upon successful completion of the program, these graduates receive a conditional job offer, and they are not entry-level, but somewhat more akin to second-year workers in terms of knowledge.

We met a graduate of the program, now employed at the Indiana plant, who was kind enough to take a break from work to join us in the class. You’re imagining a guy with forearms like canned hams, a beard, and a lot of tattoos, aren’t you? Nope. A young lady. She is now a team leader, having been promoted twice. Now 23 years old, she purchased property and started building her own home at 21, and moved in a year later. How many young college grads in your family were homeowners at age 22?

Speaking to Dr. Goggins one-on-one, I learned that this community has started to bust the dirty work myth. “Before we began, about 80% of our high school graduates went directly to college. Now it’s 60%.” Your instinct is to view this change as negative, but Dr. Goggins went on to explain, “Although nearly 80% enrolled in college programs and began to pay for it out of pocket or with loans, only about 60% ended up graduating.” As you can see, metrics can sometimes offer a false impression. The only sadder thing than a young adult with a college degree and school debt is a person with college debt and no degree at all. Dr. Goggins explained that many students who may have been a poor fit for a four-year program now secure well-paying jobs immediately upon graduation.

Line work is a job with a living wage and no ceiling (we’ll get to that last). However, some students thrive on the STEAM-focused nature of the program. For students who wish to pursue further education before entering the workforce, Ivy Tech Community College offers a two-year program with college credits in advanced manufacturing. The credits earned there are transferable toward a four-year degree in advanced manufacturing. Other students may want to go even deeper into STEAM coursework. Toyota offers an Advanced Maintenance Technician (AMT) program in partnership with Vincennes University, which enables students to earn an AMT degree while gaining hands-on work experience with Toyota. They then have the opportunity to be hired directly into their Maintenance Technician department as a full-time employee. With Toyota sponsorship, students can earn degrees debt-free.

At the plants, we toured the employee educational centers where hands-on training is combined with classroom work, covering basic principles all the way up to advanced robotics. Aside from the line workers and vehicle engineers, there is a large group of highly talented technicians, tradespeople, and engineers who maintain the line itself and the extensive facility. Let’s call this the Plant Engineering Team. Here, workers of a wide variety of skill sets do everything in the plant. There are licensed electricians, electrical engineers, and engineers of all stripes. Think of the plant as a spaceship or submarine. If it breaks, the people inside fix it. If it needs an upgrade, they make it happen. And cutting-edge, high-tech methods are just assumed. Literally hundreds of technical staff are required to operate a vehicle manufacturing plant.

Would You Want Your Child To Work In the Same Factory You Do? - Tom and Kyle Wipert

On-site at Toyota’s Kentucky plant is a think tank of sorts called the Toyota TILT Lab. Senior engineers, such as lab leader Tom Wipert, work closely with young co-op engineering program students and recent graduates. Tom embodies the “generational plant” theme at Toyota Kentucky. Workers at the plant believe that there are numerous opportunities for their family members and would highly recommend Toyota as an employer. In Tom’s case, his son is a mechanical engineer at the plant, but not in the think tank; instead, Kyle designs dies for the plant’s stamping presses that make parts for Toyota’s vehicles.

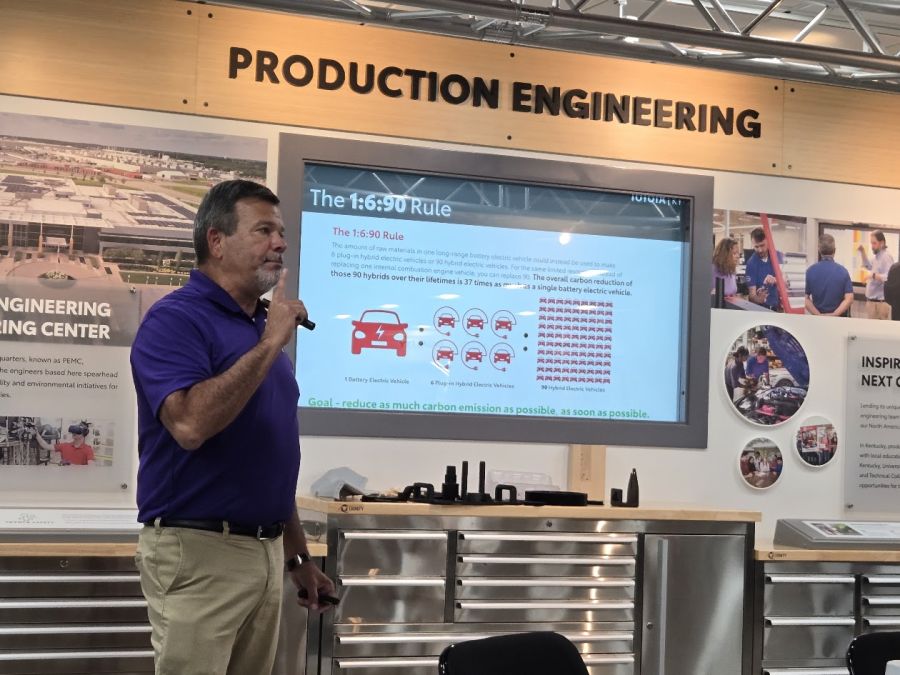

Busting the “Assembly Plant Only” Myth

One way many naysayers swipe at U.S. automotive manufacturing is to falsely claim that the plants “simply assemble, but don't actually build vehicles.” While the term "assembly" is certainly one applied to plants, it is often misunderstood by outsiders and intended as a pejorative. In the case of Toyota and Kentucky in particular, they don’t just assemble cars. They build the machines that build the cars. Often using components that they source from subsidiaries or OEM suppliers, but in many cases literally from scratch. The plant has its own stamping die fabrication. It also has an additives lab, a.k.a. 3D printer shop, with state-of-the-art repair, improvement, and fabrication of parts. These include carbon fiber parts that are often stronger than the ones that come standard on robots and other equipment. The additives lab showed us an “end-of-arm tool” assembly that they had improved. Think of a metal structure with many individual parts about the size of a step stool. The part would cost tens of thousands of dollars from the OEM, which initially built the robot. The additives team re-engineered the assembly to create a single part that is both lighter and stronger, utilizing 3D-printed carbon fiber. This change was beneficial as it reduced strain on the equipment. They produced it very quickly and at a significantly lower cost point than if it had been fabricated using traditional methods. The fact is that Toyota not only builds its cars in America, but it also builds much of the machinery that produces the cars.

Unlimited Opportunity Within Toyota’s Plants

Earlier in the story, I mentioned that workers who enter Toyota manufacturing plants as entry-level line workers have unlimited potential. The perfect example of this is the plant’s president, Kerry Creech, one of the Kentucky plant’s longest-serving employees. Mr. Creech joined the production line in January 1990. His early work was primarily in the quality control end of the business, and he was promoted eight times, most recently from VP of Manufacturing to Plant President. It seems fitting that a company built on a foundation of Kaizen, or constant improvement, would have a quality expert as the leader of its oldest and largest U.S plant.

Coincidentally, Mr. Creech and I began our professional careers in the same year. During an executive roundtable with Mr. Creech and other Toyota plant employees, each member of my group was allowed to ask one or two questions. I asked Mr. Creech, “What’s it like when you pass one of the folks you started with early in your career at the plant?” After witnessing Mr. Creech snap off fast, accurate answers about the plant’s capacity and capabilities, I didn’t expect Mr. Creech to take a long pause to think over the question. When he was ready, he answered, “Well, many of my fellow workers have retired by now.” Mr. Creech stopped again and started to become emotional. He said, “Let’s just put it this way. I strive to be a person my coworkers would greet warmly if we met shopping at Walmart. I don’t want to have to hide behind the aisle. I plan to retire in a few years, and I want to go out as a respected member of this community.”

Manufacturing Misunderstandings - Not a Dirty Job

My takeaway from spending time in two of America’s largest manufacturing plants of any kind, both operated by Toyota, is that most folks in our country who don't work in manufacturing have a misguided impression of what it means to “work in a factory.” It’s easy to assume that factories only offer dirty, physically demanding jobs with limited economic gain for the workers. Visiting the plants, I saw firsthand that the plants are clean, bright, and quiet. Toyota has cutting-edge programs to ensure worker health and longevity. Many of the jobs are high-paying and high-tech. The type of work I would have jumped at during my engineering career.

Walking the plant over two days, I met dozens of employees who stopped to chat. Most start with “I’ve been with Toyota for 17 years,” or “ I started here 24 years ago…” The management team members we met all have a personal commitment to the Toyota team they themselves create. One manager in the Indiana plant said when he introduced himself, “My commitment is to help my co-workers have the best career they can, be humble, and offer daily positive feedback to my fellow team members for work well done.”

America’s Manufacturing Future - Toyota Offers a Proven Model

My two-day visit to Toyota’s Indiana and Kentucky operations opened my eyes to what America’s manufacturing future can be. What I observed wasn’t just a company building vehicles, but rather a company that helps people, strengthens communities, and builds futures. From first-grade classrooms where social and technical skills are nurtured side by side, to clean, bright, and quiet high-tech production floors where team members on the production line are partners in innovation, Toyota has created a template for how American manufacturing can rise again. America’s manufacturing revival won’t come from politics or a single technology, but from generational investment, commitment, and community connection. If what I saw in Toyota’s Princeton and Georgetown manufacturing facilities is any indication, the next generation of American builders won’t just keep up, they will lead.

Please tell us in the comments below if you were surprised by what this story revealed.

Toyota USA Facts

- Toyota is a public company traded on the New York Stock Exchange (NYSE: TM)

- Toyota Motor North America, Inc. (TMNA) is headquartered in Plano, Texas

- Toyota directly employs about 48,000 people in the U.S. working in design, engineering, and manufacturing.

- Toyota’s first manufacturing enterprise was established in 1974 through its acquisition of Atlas Fabricators, which was subsequently renamed Toyota Auto Body California, TABC, Inc. It made truck beds. This U.S. in-sourcing was a direct result of President Johnson’s import tariff on trucks (Still in effect today).

- In 1994, Toyota partnered with General Motors at a plant in Fremont, California, to build small cars. It was eventually traded to Tesla, with Toyota acquiring a significant percentage of Tesla stock in the transaction.

- Toyota Motor Manufacturing Kentucky (TMMK), featured in this story, broke ground in Georgetown, Kentucky, in May of 1986 and began producing U.S.-made Camry cars two years later.

- Today, Toyota operates 11 manufacturing plants in the United States.

- Toyota produces vehicle structures and bodies from raw steel, builds powertrains, molds plastics, and creates many other components inside the United States for the vehicles it builds.

John Goreham is the Vice President of the New England Motor Press Association and an expert vehicle tester. John completed an engineering program with a focus on electric vehicles, followed by two decades of work in high-tech, biopharma, and the automotive supply chain before becoming a news contributor. He is a member of the Society of Automotive Engineers (SAE int). In addition to his eleven years of work at Torque News, John has published thousands of articles and reviews at American news outlets. He is known for offering unfiltered opinions on vehicle topics. You can connect with John on LinkedIn and follow his work on his personal X channel or on our X channel. Please note that stories carrying John's by-line are never AI-generated, but he does employ grammar and punctuation software when proofreading and he also uses image generation tools.

Images by John Goreham. The last image of the Kentucky plant from above is a photo of a slide shown to the author by Toyota.

Set as google preferred source

Comments

Should ship production back…

Permalink

Should ship production back to Japan. Maybe then toyota would be worth a damn.