Historically, a couple of notable vehicles used plastic body panels instead of metal to reduce weight, resist dents, and simplify manufacturing. The Pontiac Fiero, launched in 1984 and produced until 1988, was the first mass-produced mid-engine car from a U.S. automaker and featured plastic body panels mounted on a steel spaceframe. The Saturn S Series, introduced in 1990 and offered through 2002, also used dent resistant polymer panels over a steel structure. Both models aimed to showcase innovation and durability, but faced challenges with thermal expansion, leading to panel gaps and misalignment in extreme weather. Ultraviolet exposure sometimes caused the panels to fade or become brittle over time. Despite these issues, plastic panels reduced corrosion and were cheaper to repair.

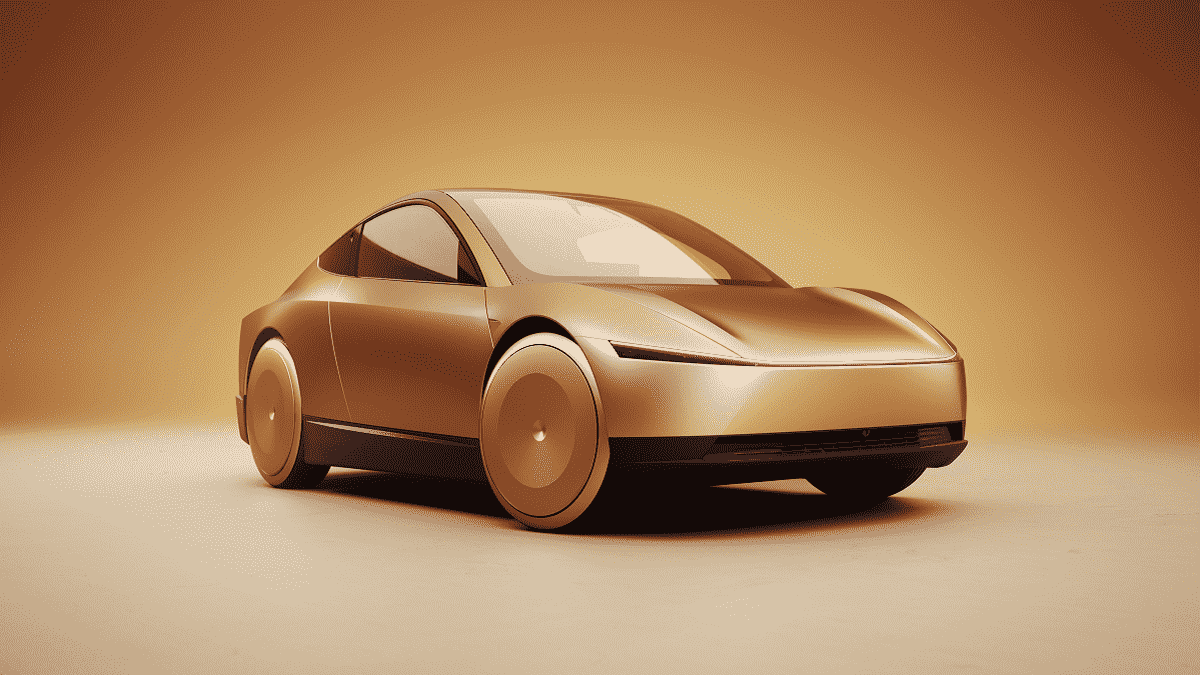

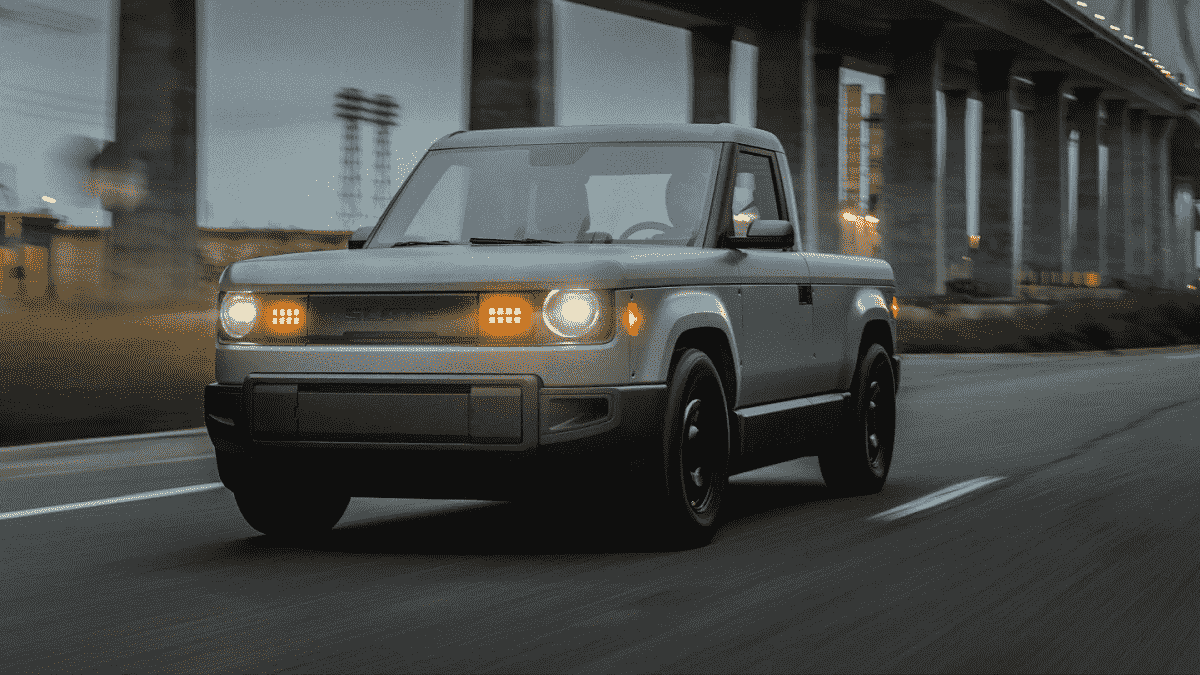

Today, Tesla’s upcoming Cybercab will use injection molded plastic panels with color integrated during manufacturing to eliminate paint processes. The Slate truck will also feature unpainted plastic panels focused on affordability, easy repair, and modular customization.

This has created several long threads on social media. Here’s a recent Reddit post by tazadazzle:

“Sounds like it’s [Slate Truck body panels] the same or similar material to the “composite” (ie plastic) material I’ve seen in the truck beds of the new Tacoma, Ridgelines, Santa Cruz. If it can hold up to the wear and tear of a truck bed it should be good for body panels?”

mister_monque responded with:

“SMART did this, offered the whole pallet of colors, change your look in a weekend

Saturn and Pontiac made great use of plastic panels as well.

none of the cladding is structural so how strong would it need to be right?”

traumatic415 added:

“Many GM cars have plastic front fenders, and the Fiero, TransSport/Lumina/Silouette MPV, and the original series of Saturns from the 90’s were all plastic clad. Practically every modern cars front fascia has been plastic for 20+ years. It’s mature technology that has held up fine!”

Plastic components have been increasingly used in automotive manufacturing to reduce weight, simplify assembly, and lower costs. In the 2001 Chevrolet Corvette Z06, GM used composite leaf springs made from fiberglass reinforced plastic to improve suspension performance. BMW introduced plastic intake manifolds in the 1990s, including on the 1995 BMW 3 Series, to reduce engine weight and increase thermal efficiency. In 2022, Koenigsegg unveiled carbon fiber reinforced plastic wheels on the Jesko hypercar, significantly reducing unsprung mass. Plastic has also been used in fuel tanks, radiator end tanks, and underbody shields across a wide range of vehicles.

The Tesla Cybercab uses plastic body panels to improve manufacturing efficiency, reduce costs, and enhance durability, making it well suited for a high-volume autonomous robotaxi. These injection molded panels are color infused during production, eliminating the need for a traditional paint shop and reducing both labor and environmental impact. Plastic is significantly cheaper and faster to mold than metal, which helps Tesla scale production while keeping costs low. The panels are also dent resistant and more durable in everyday use, making them ideal for fleet vehicles that will operate continuously in urban environments. In the event of damage, plastic panels are easier and less expensive to replace compared to metal bodywork. Additionally, plastic is lighter than metal, which improves energy efficiency and extends vehicle range. Tesla’s choice reflects a broader trend in automotive design that prioritizes cost effective materials and practical engineering for electric and autonomous vehicles instead of traditional premium finishes.

Tesla’s VP of Vehicle Engineering, Lars Moravy, shared that the company will be injecting polyurethane paint directly into the plastic during the manufacturing process. This method eliminates the need for a traditional paint shop, as the colors are embedded directly into the plastic while the panels are molded. An automotive OEM paint shop is one of the most expensive parts of a vehicle manufacturing plant. The cost typically ranges from $200 million to over $500 million. The best part is that these panels are highly resilient. If they get scratched, dinged, or worn down, the original color remains visible throughout, unlike standard painted panels, which would reveal the underlying material.

Per Tesla VP of engineering, Lars Moravy, recently stated:

“You inject the polyurethane paint at the same time that you make the plastic panels and so there's no paint shop.”

The Slate truck uses plastic body panels to reduce manufacturing costs, simplify assembly, and improve durability. These panels are made from injection molded plastic, which is less expensive and easier to produce than traditional stamped metal. Because the panels do not require painting, Slate eliminates the need for a costly paint shop, further lowering production expenses. The plastic panels are also dent and rust resistant, making them ideal for a work-focused vehicle that may face tough conditions. Since the panels are non-structural and bolted onto the truck’s steel frame, they are easy to replace or upgrade without specialized tools. This modular design allows Slate to offer a low-cost, versatile platform that is easy to maintain and repair. Additionally, customers can personalize their vehicles with vinyl wraps, offering different colors, textures, or branding without damaging the base panels. This approach balances affordability, function, and customization, making the Slate truck unique in the EV market.

Please Drop Your Thoughts in the Comments Below

Have you owned a car with plastic body panels? If so, how did they hold up over time?

Do you have any concerns about buying a car with plastic body panels?

Chris Johnston is the author of SAE’s comprehensive book on electric vehicles, "The Arrival of The Electric Car." His coverage on Torque News focuses on electric vehicles. Chris has decades of product management experience in telematics, mobile computing, and wireless communications. Chris has a B.S. in electrical engineering from Purdue University and an MBA. He lives in Seattle. When not working, Chris enjoys restoring classic wooden boats, open water swimming, cycling and flying (as a private pilot). You can connect with Chris on LinkedIn and follow his work on X at ChrisJohnstonEV.

Image sources: AI, Tesla media kit, Slate Auto media kit

Set as google preferred source

Comments

Owned a black Saturn sc2…

Permalink

Owned a black Saturn sc2. For 5 years. No problems with the panels in the Midwest. Car was garaged 90% of the time.