A loud mechanical failure has a way of rewriting a driver’s confidence in an instant, especially when it arrives during what should be routine use of a truck’s advertised capabilities.

That is the position one 2022 Ford F-150 PowerBoost owner now finds himself in after his front differential catastrophically failed at 71,457 miles while using four-wheel drive low range exactly as intended, or so he believed.

His account, shared in a PowerBoost owners group, has struck a nerve because it mirrors stories others say they have already seen play out.

The incident occurred during a winter recovery scenario that will sound familiar to anyone who actually uses a truck. While towing, the owner’s trailer slipped into a snowy ditch. With limited options, another driver offered to pull the trailer backward while the F-150 assisted under its own power.

Following the truck’s on-screen instructions, the owner shifted from 4H into 4L. There was no throttle abuse, no attempt to spin tires wildly. In his words, it was “slow, steady, no wheelspin,” with the goal of maintaining traction rather than forcing movement.

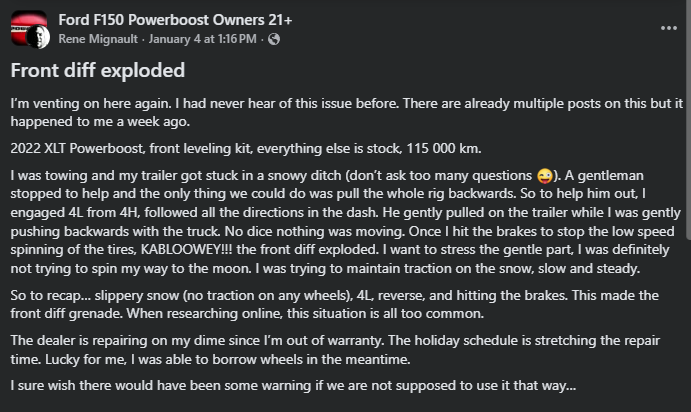

“I’m venting on here again. I had never heard of this issue before. There are already multiple posts on this, but it happened to me a week ago.

2022 XLT Powerboost, front leveling kit, everything else is stock, 71,458 miles.

I was towing, and my trailer got stuck in a snowy ditch (don’t ask too many questions). A gentleman stopped to help, and the only thing we could do was pull the whole rig backwards. So to help him out, I engaged 4L from 4H, followed all the directions in the dash. He gently pulled on the trailer while I was gently pushing backwards with the truck. No dice, nothing was moving. Once I hit the brakes to stop the low-speed spinning of the tires, boom, the front diff exploded. I want to stress the gentle part; I was definitely not trying to spin my way to the moon. I was trying to maintain traction on the snow, slow and steady.

So to recap… slippery snow (no traction on any wheels), 4L, reverse, and hitting the brakes. This made the front diff grenade. When researching online, this situation is all too common.

The dealer is repairing it on my dime since I’m out of warranty. The holiday schedule is stretching the repair time. Lucky for me, I was able to borrow wheels in the meantime.

I sure wish there had been some warning if we were not supposed to use it that way…”

That restraint is what makes the outcome so unsettling. As the tires lightly spun on the snow and the driver applied the brakes to stop the motion, the front differential failed violently. The owner describes a sharp, explosive noise that drew the attention of onlookers. The damage was not subtle. According to the dealer, the differential housing itself split, turning what should have been a recovery lesson into a major drivetrain failure.

Ford F-150:Configurability, Noise, and Long-Term Usability

- The F-150’s sheer configurability creates a usability gap across trims, where work-focused models emphasize durability and simplicity while higher trims introduce complexity that can conflict with job-site use.

- Cabin noise levels vary significantly by tire choice and suspension setup, making road and wind noise a more noticeable factor in lower trims designed for payload rather than comfort.

- Bed height and tailgate design influence daily loading more than capacity figures, particularly for users frequently handling tools or materials without ramps.

- Long-term ownership favors familiarity, as widespread parts availability and service infrastructure reduce downtime compared with newer or less common truck platforms.

At just over 71,458 miles, the truck was out of warranty, leaving the owner fully responsible for the repair bill. Holiday scheduling delays only added to the frustration, though he was fortunate enough to borrow wheels in the meantime. What lingered more than inconvenience, however, was confusion. There was no warning from the truck that this maneuver was unsafe. No indication that using 4L in reverse under load could destroy a core drivetrain component.

As the post circulated, explanations came quickly, and not all of them agreed. Some pointed to the truck’s front leveling kit, arguing that altering suspension geometry pushes CV axles beyond their ideal operating range and increases stress on the differential under load. Others countered that the more critical factor was engaging 4L in reverse while towing, a condition they claim these systems do not tolerate well, regardless of modifications.

The owner clarified that the failure was not a broken CV axle or driveshaft, but a cracked differential housing, suggesting internal forces exceeded what the case could handle. That detail matters. A broken axle is often a sacrificial failure. A split housing suggests something more abrupt and structural. It also fuels the owner’s claim that this is not an isolated incident, pointing to similar reports found online involving F-150 PowerBoost trucks in comparable situations.

What makes this story resonate is the gray area it exposes. Trucks are marketed as tools, with four-wheel drive low range presented as a solution for slow, controlled movement in difficult conditions. Snow, towing, low speed, and careful throttle application all sound like textbook use cases. Yet buried beneath that marketing is a web of caveats, some documented, some implied, and others only learned the hard way.

The PowerBoost adds another layer of complexity. With hybrid torque delivery, instant response, and regenerative braking blending with conventional braking, driveline loads may behave differently than they did in older, purely mechanical trucks. Whether that contributed to this failure is unclear, but it raises legitimate questions about whether all usage scenarios are equally understood by owners and engineers alike.

For technicians, the lesson may be about modifications and operating limits. For owners, it is a reminder that modern trucks are less forgiving than their rugged image suggests. And for Ford, it is another data point in a growing conversation about front differential durability in real-world conditions, especially when those conditions involve low-speed, high-load maneuvers that trucks are expected to handle.

The owner’s frustration ultimately centers on one simple idea. If a truck can destroy its front differential while being used carefully, slowly, and without wheelspin in a snowy recovery, then either the system is more fragile than advertised, or its limitations are not being communicated clearly enough. Being out of warranty may explain the bill, but it does not answer the bigger question of whether this failure should have happened at all.

Image Sources: Ford Media Center

Noah Washington is an automotive journalist based in Atlanta, Georgia. He enjoys covering the latest news in the automotive industry and conducting reviews on the latest cars. He has been in the automotive industry since 15 years old and has been featured in prominent automotive news sites. You can reach him on X and LinkedIn for tips and to follow his automotive coverage.

Set Torque News as Preferred Source on Google

Comments

Don't believe for one second…

Permalink

Don't believe for one second this front diff housing just up and failed under the most gentle of conditions. Could be the housing was previously stressed and just didnt break at that time, but it's integrity was compromised, could be that in the process of getting stuck it hit something such as a big rock at the edge of the road or ditch. I'm not the Forf fan that I used to be, as the ecoboost seems to be the way they've chosen to move forward and I wouldn't touch one with a 10 ft pole...trucks shouldn't be over complicated, as it takes away from their value, doesn't add to it. Reliability is king!

I was a factory rep for Ford…

Permalink

In reply to Don't believe for one second… by Michael Griffith (not verified)

I was a factory rep for Ford for years. The products weren't perfect, but they were often abused to the point of failure, as well.

People often buy pickup trucks and treat them like they are indestructible.

While four wheel low is standard on most four wheel drive vehicles, it is something not to be used often. It is an emergency gear only. It is not meant to be used regularly.

Based on the story, and my experience, that is what happened here. We used to see it all the time.

Vehicle modifications often caused failures that the customer blame on the truck. Once modifications, like a lift kit, are installed on the truck, anything could happen.

We used to see a lot of over-weight towing causing failures. An alarm went off everytime I ran into a truck with a combination of excessive brake wear/transmission failure.

Apart, the parts could have many potential reasons for failure. Together, it automatically told us that the truck was towing well beyond its stated capacity.

The constant push-pull of the trailer strained both systems past their stated design limit. We knew the over-towing was extreme, because the stated ability of the truck was 30% lower than indicated.

Stripped chassis trucks were a huge problem with weight. Used for work trucks, and RV drivetrains. They were regularly overloading by the customer or the company that used it.

RVs are particularly bad. RV manufacturers would often build the cabin upto the limit listed for the chassis. Leaving no room for the weight of fuel, passengers, and cargo.

All types of truck were always an issue, because of customer overuse. Yes, design and build also causes issues, but customer abuse and overuse are all to often overlooked when cases like this come up.