In the brutal, capital-intensive transition from internal combustion to electric vehicles, most legacy automakers have opted for a pragmatic, if compromised, approach: retrofitting old factories. They are painstakingly ripping out greasy engine assembly lines and replacing them with clean, quiet battery-pack stations, attempting to build the future on the foundations of the past. And then there’s Volvo. The Swedish automaker, in a move that is both bold and deeply strategic, has broken ground on a brand-new, €1.2 billion factory in Slovakia designed for one purpose only: to build electric cars. This isn't just another factory; it's a clean break from the past and a powerful statement of intent. By choosing to build from scratch rather than renovate, Volvo is making a calculated bet that the future of automotive manufacturing requires a fundamental rethink, not just a renovation.

The Unseen Advantages of a Blank Slate

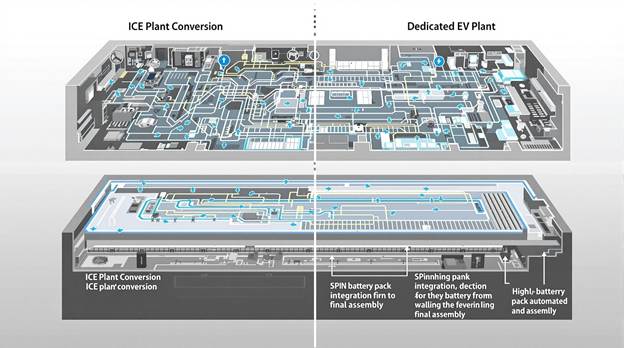

On the surface, retrofitting an existing plant seems like the fiscally prudent choice. The building is there, the workforce is in place, and the supply chains are established. But building an EV in a factory designed for gasoline cars is like trying to build a smartphone on a typewriter assembly line. It’s possible, but it’s hopelessly inefficient. An EV has roughly 30-40% fewer parts than its combustion-engine counterpart. The entire manufacturing flow is different. The heaviest component—the battery pack—is installed at the very beginning, forming the floor and chassis, a process known as the "skateboard" design.

A dedicated EV plant, like Volvo's new facility in Kosice, Slovakia, can be designed around this reality. The logistics can be optimized for a simpler powertrain, with suppliers for batteries and electric motors located closer to the assembly line, or even on-site. The factory floor can be laid out for maximum automation and a more streamlined, linear workflow, free from the constraints of a century of ICE-based design. Furthermore, the workforce can be trained from day one on the specific high-voltage systems and software integration skills required for EV production, creating a more specialized and efficient team. Retrofitting often means retraining a workforce steeped in mechanical traditions, a significant and often underestimated challenge.

A Strategic Investment at a Pivotal Moment

This massive investment comes at a time when Volvo is in a position of relative strength, yet facing an uncertain market. The company reported a second consecutive year of record sales and profits in 2024, with revenues topping SEK 400 billion for the first time. Critically, fully electric cars accounted for 23% of its total global sales, a share that leads most legacy premium automakers. This profitability provides the capital and the confidence to make a long-term bet like the Slovakia plant.

The new facility, set to produce up to 250,000 cars per year starting in 2026, will be crucial for helping Volvo achieve its ambitious goal of becoming a fully electric brand by 2030. It will provide a much-needed boost in European production capacity for its next generation of EVs, insulating the company from potential tariffs on cars built in China. While Volvo, like all automakers, anticipates a more challenging market in 2025, this plant isn't about next year's sales figures. It's a strategic move to lower production costs, increase margins, and improve the quality of its EVs for the next decade.

The Start of a Manufacturing Revolution?

Volvo is not alone in its thinking, but it is at the vanguard of a trend that is likely to accelerate. While Ford and GM have focused on high-profile conversions of historic plants, they are also investing in new, dedicated EV facilities. However, Volvo's commitment to making its first new European plant in 60 years a pure EV facility is a powerful signal. It suggests that as EV sales volumes continue to climb, the math will increasingly favor bespoke factories over compromised conversions.

The long-term efficiencies and quality control benefits of a purpose-built EV plant are simply too great to ignore. We are likely to see a "great divergence" in automotive manufacturing over the next decade. Automakers who commit to building new, hyper-efficient EV plants will likely gain a significant competitive advantage in terms of cost and quality over those who remain tied to their legacy ICE infrastructure.

Wrapping Up

Volvo's decision to build a new, EV-only plant in Slovakia is far more than a simple expansion of its manufacturing footprint. It is a strategic masterstroke, a clean break from the operational compromises and inefficiencies of the past. By designing a factory entirely around the unique architecture of an electric vehicle, Volvo is positioning itself to be a leader in the next era of automotive production. This plant is a multi-billion-dollar bet that the best way to build the car of the future is not to renovate the factories of the past, but to create a new foundation from the ground up. It’s a bold, forward-looking move that the rest of the industry will be watching very, very closely.

Disclosure: Images rendered by Artlist.io & Midjourney

Rob Enderle is a technology analyst at Torque News who covers automotive technology and battery developments. You can learn more about Rob on Wikipedia and follow his articles on Forbes, X, and LinkedIn.

Comments

Why Slovakia and not Sweden?

Permalink

Why Slovakia and not Sweden?