The automotive world is facing a significant design reckoning. For the better part of a decade, the hallmark of a futuristic, premium electric vehicle has been the flush, retractable door handle. Popularized by Tesla and subsequently adopted by manufacturers ranging from Mercedes-Benz to Hyundai, these handles offer a sleek aesthetic and crucial aerodynamic gains. However, a reported upcoming regulatory shift in China is set to slam the door on this trend.

China, the world's largest auto market and a massive hub for EV adoption, is reportedly moving to ban fully retractable, electronic-release door handles starting in 2027. This decision follows numerous high-profile incidents where occupants were trapped inside burning or submerged vehicles because the electronically actuated handles failed to deploy after a crash.

This isn't just a minor design tweak; it’s a fundamental rethink of how form relates to function when safety is on the line.

A Tale of Two Realities: The sleek, flush door handle of a modern EV (left) versus the brutal reality of a first responder using a hydraulic tool to breach a car door at a crash scene (right). China's new regulation aims to bridge this dangerous gap.

The Dangers Hidden in Sleek Design

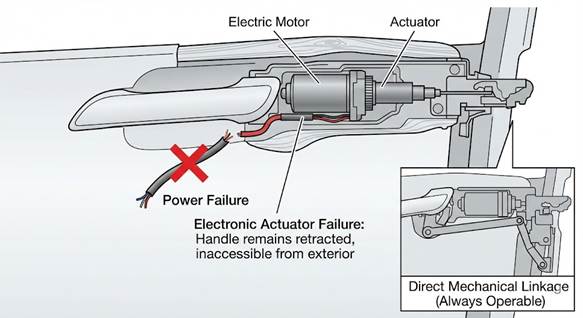

Before discussing the ban, it is vital to understand the hazard. The primary issue with electronic flush handles—often called "hidden" or "pop-out" handles—is their reliance on the vehicle's low-voltage power system to present themselves to the user.

In normal operation, they are convenient and cool. But in a severe collision, the vehicle’s primary power loop is often severed to prevent electrical fires. When power is lost, these handles frequently remain retracted flush against the body panel.

For passengers trapped inside, the confusion of finding a mechanical manual release in a panic situation can be fatal. But the danger is even more acute for rescuers on the outside.

First responders operate within the "golden hour," where every second spent accessing a patient significantly impacts survival rates. Traditional handles offer an immediate, intuitive grab point to wrench a door open or apply hydraulic rescue tools. When faced with a smooth sheet of metal following a crash, rescuers lose precious time trying to figure out how to breach the vehicle. There have been tragic, documented instances where bystanders and first responders were unable to extract victims from burning EVs due to failed handle deployment.

The Failure Point: This diagram illustrates how a loss of power can disable an electronic handle, while a mechanical linkage remains operative.

The Pros and Cons of China’s 2027 Ban

China’s impending regulation is a blunt instrument aimed at a nuanced problem, and it comes with clear advantages and significant downsides for the industry.

The Advantages: The primary benefit is undisputable: increased post-crash survivability. By mandating handles that are mechanically accessible from the exterior at all times, the legislation prioritizes human life over drag coefficients. It removes a layer of technological complexity that has proven fragile in crisis situations. It also simplifies standard operating procedures for emergency personnel across the globe, as Chinese manufacturing trends often influence global standards.

The Disadvantages: The immediate negative impact will be on vehicle efficiency and design. In the EV race, range is king. Flush handles aren't just for looks; they reduce turbulence along the vehicle's flank. Returning to protruding handles will add drag, potentially shaving a few miles off rated ranges—a metric automakers fight tooth and nail for. Furthermore, car designers will mourn the loss of the "seamless" futuristic aesthetic that has defined the current generation of vehicles.

Why Were They Allowed in the First Place?

Given the known risks and the gruesome nature of the accidents associated with entrapment, many ask why regulators allowed these designs initially.

The answer lies in the lag between innovation and regulation. Automotive safety standards have historically been reactive, written in blood after new technologies reveal their dangers. When Tesla and others introduced these handles, existing regulations generally only required that a door have a latching system and a means of operating it. They did not anticipate a scenario where the "means of operating it" was entirely dependent on a fragile electronic circuit.

Furthermore, the push for EV adoption incentivized any feature that improved range. Regulators were initially focused on battery safety and crash structure integrity, overlooking the interface mechanism of the door itself. The cool factor and the efficiency gains blinded the industry to the potential failure modes of replacing a simple mechanical lever with actuators and software.

What Is Likely to Replace These Flush/Retractable Handles

The ban in China does not mean a return to the chunky black plastic handles of a 1995 sedan. Designers will need to innovate, but within new constraints.

We are likely to see a rise in "semi-flush" designs. These are handles that sit nearly flush with the bodywork for aerodynamics but have a distinct mechanical lip or indent that allows a hand to physically grab and mechanically actuate the latch at any time, regardless of power status.

Another option is the "fixed aero" handle—a modern take on traditional designs, sculpted tightly to the body to minimize drag, ensuring mechanical redundancy without relying on motors to "present" the handle. The key will be ensuring a direct mechanical link from the exterior to the latch mechanism.

The Future of the Handle: A "semi-flush" handle design like this one offers a compromise, providing a mechanical grab point while minimizing aerodynamic drag.

Regulatory Reforms Needed for the Future

The saga of the flush door handle highlights a critical weakness in modern automotive regulation: the failure to account for "complex system failures" in an increasingly digitized automobile.

To ensure this doesn't happen again, regulatory bodies (like the NHTSA in the US, ECE in Europe, and CATARC in China) need to shift from purely mechanical component testing to holistic system-failure analysis.

New regulations must mandate crash tests specifically designed to sever low-voltage power, verifying that all ingress and egress points remain operative immediately post-impact without special knowledge. We need standards that require "fail-safe mechanical redundancy" for all critical safety systems, meaning if the computer dies, the physical mechanism still works instinctively.

Testing for Safety: New regulations must include rigorous post-crash testing to ensure door handles remain functional even after a severe impact and power loss.

Wrapping Up

China’s move to ban retractable door handles by 2027 is a watershed moment for automotive design. It signals that the industry's obsession with sleek aesthetics and minor range increments has, in this specific area, crossed a safety red line. While designers may lament the loss of a clean flank, and engineers will grumble about drag coefficients, the return to handles that work when it matters most—during a catastrophic power failure—is a necessary correction. This regulation serves as a stark reminder that in the rush toward the software-defined vehicle, we must not forget the physical realities of escaping one during an emergency.

Disclosure: Images rendered by Artlist.io

Rob Enderle is a technology analyst at Torque News who covers automotive technology and battery developments. You can learn more about Rob on Wikipedia and follow his articles on Forbes, X, and LinkedIn.

Set Torque News as Preferred Source on Google