Tesla Robots and Stamping Reveal How a Tesla Is Made

In Tesla's Giga Berlin factory in Brandenburg, Germany, we see through the eyes of a flying drone that goes through Tesla's factories showcasing its machines, robots, and stamping process. This gives a glimpse into how Tesla is able to scale production to such high volumes.

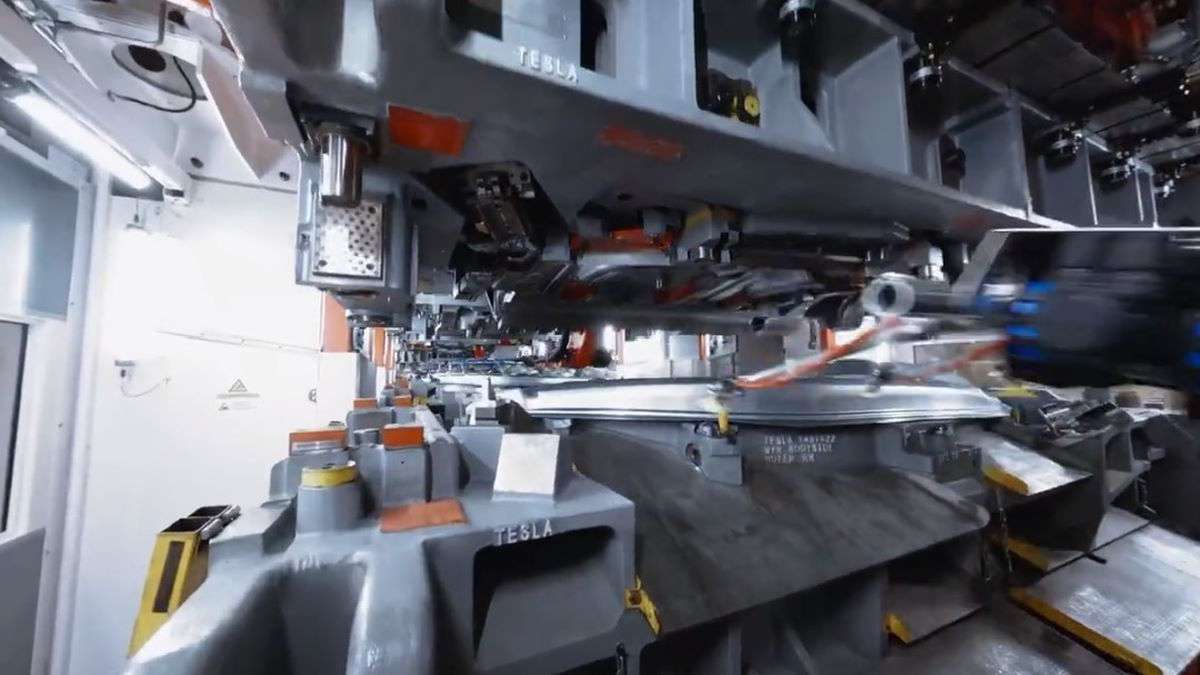

The drone first goes through a conveyor belt with sheets of metal on it. A robot picks up these sheets of metal and places them down, and a second robot take the sheet of metal that is coming to it and places it in between a stamping machine. This machine forms the metal into a shape that will fit on the car instead of being a flat shape.

That piece of metal that was tamped is then moved to a machine that takes it and stamps it a second time. Tesla has created a stamping machine that has the exact form its sheets of metal for its cars should take, and there is no variation on these.

Later, there is a conveyor belt with these completed metal frames, all being inspected by Tesla workers.

Further along, we see a Tesla worker working with the molten material used by the Giga Press from Idra. The drone flies very close to the Giga Press and watches as a giant robot arm takes the completed casting out of it - well-formed to be a large portion of a Tesla vehicle.

Two of the frames that were stamped on the conveyor belt are then combined with the casting from the Giga Press to form what looks like most of a Tesla vehicle. This is all done by robots and no human intervention.

Down the assembly line further, robots continue to weld parts of the car together. After that, with the completed car frame, human workers inspect the vehicles to make sure there are no issues.

Robots then take the cars along another process to the paint shop area, where the car is dipped and coated in white paint. Multiple screens with Tesla employees show the further progress of the Tesla vehicles.

There is now a frunk and insides being placed in the cars along the assembly line. As you get further along, the completed car with tires is shown, all completed with an assembly line and robots. At the end, there is a Tesla tunnel with the word Tesla on it that the completed cars come out of.

It's a stunning and very automated process for Tesla to make its vehicles in Giga Berlin.

You may also be interested in:

- Tesla Generation 3 vehicles will end gas and EV companies.

- Tesla Cybertruck will benefit from 1 MW charging speeds.

- How regenerative braking works in EVs.

Tesla Production at Giga Belrin

I am stunned at the sheer amount of automation that is taking place at Giga Berlin - and probably at all of Tesla's other factories. Tesla seems to have a simple process for making its vehicles, but the path to get there was probably a lot of trial and error.

Tesla's process is this:

* Create metal sheets for each side of the car

* Stamp those metal sheets into the side frame form

* Create a giga casting for the base frame of the car - front and back

* Eventually, create a single casting for the frame of the car

* Have robots weld the car frames and the stamped metal sheets to each other

* Have humans inspect this along the way

* Put seats, electronics, the glass roof, windshield, and everything else together

Eventually, Tesla wants to be able to produce a vehicle in the same amount of time it takes to make a toy car. If Tesla can get to the point where the entire frame of the car, including the sides, is made rapidly, from a casting, this is going to be a leap in production.

How Tesla could get to the point that the entire car frame, including the side portions, which are all separate right now, is a good question. Tesla's best engineers are most likely thinking about this, as the Model 2 and compact vehicles will need to be made with an even simpler process to reach millions of vehicles produced per year.

I think Tesla is around 3,500 vehicles per week at Giga Berlin now and look forward to Tesla reporting on this number with an update.

I found this video very cool, showing Tesla vehicles being built from start to finish. What did you think of it?

In Related News: Tesla Model Y to Lead European Car Market

Ever flown through an active stamping press?

Giga Berlin pic.twitter.com/nlI36efidf— Tesla Europe (@tesla_europe) February 6, 2023

Leave your comments below, share the article with friends and tweet it out to your followers.

Jeremy Johnson is a Tesla investor and supporter. He first invested in Tesla in 2017 after years of following Elon Musk and admiring his work ethic and intelligence. Since then, he's become a Tesla bull, covering anything about Tesla he can find, while also dabbling in other electric vehicle companies. Jeremy covers Tesla developments at Torque News. You can follow him on Twitter or LinkedIn to stay in touch and follow his Tesla news coverage on Torque News.