Toyota announced today that the company has made a breakthrough in semiconductor manufacturing that will allow it to use silicon carbide (SiC) as the substrate for the integrated circuit chips in power control units (PCUs). This breakthrough will be good for a 10% fuel efficiency gain in hybrid vehicles. Most likely, the biggest gain will come in vehicles that are already fully optimized for fuel efficiency, like the Prius and CT 200h hybrid from Lexus. Toyota plans to have cars on the road with this technology within the year and to commercialize the technology by 2020.

About a year ago Mr. Satoshi Osigo, the managing officer of Toyota, outlined his vision for the next generation Prius. We covered the story then, and the one thing we reported, but had no good information on, was how Toyota would again increase the efficiency of the "Hybrid Synergy Drive" in the Prius by 5%. Frankly, since its thermal efficiency is already the leader in the world among cars powered only by gasoline, we were cautiously pessimistic that a simple update to the current drivetrain would get Toyota the added 2.5 MPG increase it needed to meet its target.

We surmised that Toyota would have to do some form of radical redesign along the lines of the Chevy Volt and Honda Accord hybrid in order to move the needle once again. Maybe we were wrong and Toyota’s current design might still have some juice in the lemon to be squeezed. According to today’s announcement, Toyota already has achieved a 5% increase in fuel economy using this technology in test vehicles.

The substrate for semiconductor chips is a wafer sliced from an ingot of pure silicone. The first layer (called the epitaxial layer) is an oxide layer, usually silicone dioxide, that is created in an oven using incredibly high energy and heat. There are dozens of layers built up on top of this foundation using some of the world's most complex machines.

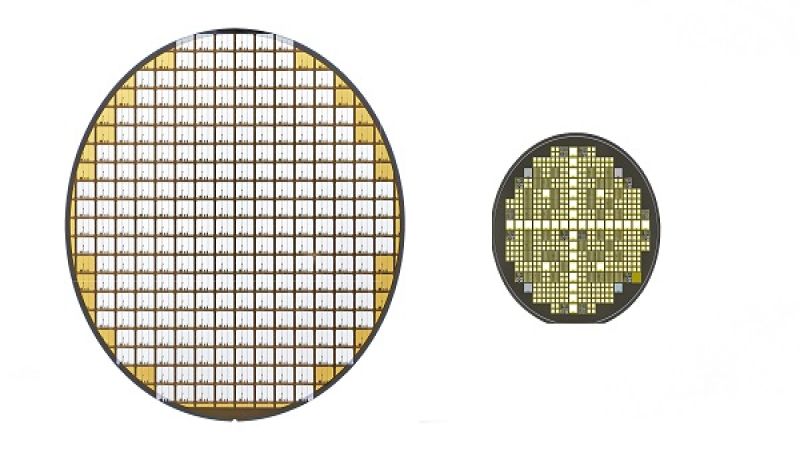

Toyota says that SiC chips use less energy when switching circuits on and off. The result is that the coil and capacitor in the PCU can be up to 40% smaller and use less energy. The photos released, and some facts from Toyota do show how the form factor of the PCU is much smaller in the new units made with the technology.

Toyota said in a statement today that “PCUs play an important role in hybrids and other vehicles with an electrified powertrain: they supply electrical power from the battery to the motor to control vehicle speed, and also send electricity generated during deceleration to the battery for storage. However, PCUs account for approximately 25 percent of the total electrical power loss in HVs, with an estimated 20 percent of the total loss associated with the power semiconductors alone.”

Toyota’s research into SiC chips began in the 1980s. Since the first Prius was launched in 1997, Toyota has moved its SiC research in-house. In 2007 the company ramped up its involvement with Denso on joint research of the technology. This past December Toyota built its own clean room at the Hirose plant which is where the company’s main research and development on electronic control units and semiconductors takes place.

Note: The author spent 18 years involved in the semiconductor industry in engineering, product management, and marketing. This is the first story in his 3 years of automotive reporting in which that background proved directly relevant.

About the main photo - The larger image is a conventional SiO2 based wafer. The smaller is offered by Toyota as an illustration of how the SiC chips may be smaller. In fact, the wafer size is irrelevant.

Related Topics:

Three reasons why the Toyota Prius outsells the entire electric car market

Will the new 2015 Prius reverse sales crash?

Set as google preferred source