Electric vehicle trends are driving in the right direction. Consumer demand is strong as exemplified by global electric vehicle sales exceeding 10% market share for the first time last year. A slew of sub $30,000 EVs are entering the market. Battery costs are plummeting - the cost per kilowatt-hour of lithium-ion batteries dropped by 89% in a decade. They went from around $1,100 per kWh in 2010 to around $137 per kWh in 2020, and they continue to drop. This has led to a lot of social media discussion about what the near future holds for electric vehicles.

Here’s a recent post on Reddit by JamesVirani that started a long thread about how the EV environment will look in five years:

“5-10 years from now the battery technology we are using today will look comically antiquated, in the same way that the range and technology of a 2014 Nissan Leaf compared to the average EV being produced today looks abysmal.”

WeldAE responded with:

“The average EV will look a lot like the range performance of a Model 3 LR today. Charging performance will be a good bit better and will look more like a 2024 Porsche Taycan, and the average eV will have a battery slightly over 100kWh in it. Still ranges won't be much better than the Model 3 in most EVs because it's more than enough and most EVs will be bigger and less aero than a Model 3. Between the under 15 minute charging speed to add 200 miles and the fact that chargers are everywhere, range won't really matter very much anymore.”

itruns66 added:

“5 years ago: Chevy Bolt, 2nd gen Nissan Leaf, Models 3, X & S with the Y about to be launched. Ford is developing the Mach E, Lightning and E-Transit. No heat pump, Octovalve or Giga castings. No FSD. Cells are still pretty darn expensive. China's doing China stuff like letting Tesla build a functioning Giga Factory in under a year.”

The following are EV-related technologies and standards that are rolling out or have a high probability of entering the market.

Charge Plug Standardization – NACS Is The New USB

There are currently three types of charge plugs used in the United States: the Combined Charging System (CCS), CHAdeMO, and North American Charging Standard (NACS) which is Tesla’s proprietary connector. This year, the industry is moving toward standardizing around the NACS connector. This shift offers several advantages. For consumers, it simplifies charging access by ensuring compatibility across more charging stations, reducing confusion and range anxiety. For manufacturers, it lowers production and infrastructure costs by streamlining designs and reducing the need to support multiple plug types. Standardization to NACS promises a more efficient and accessible EV charging network nationwide.

The 48-Volt Architecture

Love it or hate it, the Tesla Cybertruck has some revolutionary tech inside including its 48-volt electrical architecture. Offering a vehicle with a 48-volt architecture was very difficult to implement and Tesla was the first high-volume automobile company to accomplish it. It was difficult to implement because the automotive industry is currently dependent on 12-volt components. Most suppliers lacked compatible 48V parts which forced Tesla to redesign systems in-house. Higher voltage introduced safety and electrical noise challenges, requiring advanced engineering. Supply chain limitations and technical hurdles made the transition uniquely complex.

What are the benefits of a 48V architecture? As any electrical engineer can tell you, "I squared R" (I²R) represents the power dissipated as heat when a current (I) flows through a resistance (R). The full equation is P = I²R where P is the power in watts, I is the current in amperes, and R is the resistance in ohms. Make sense? Good.

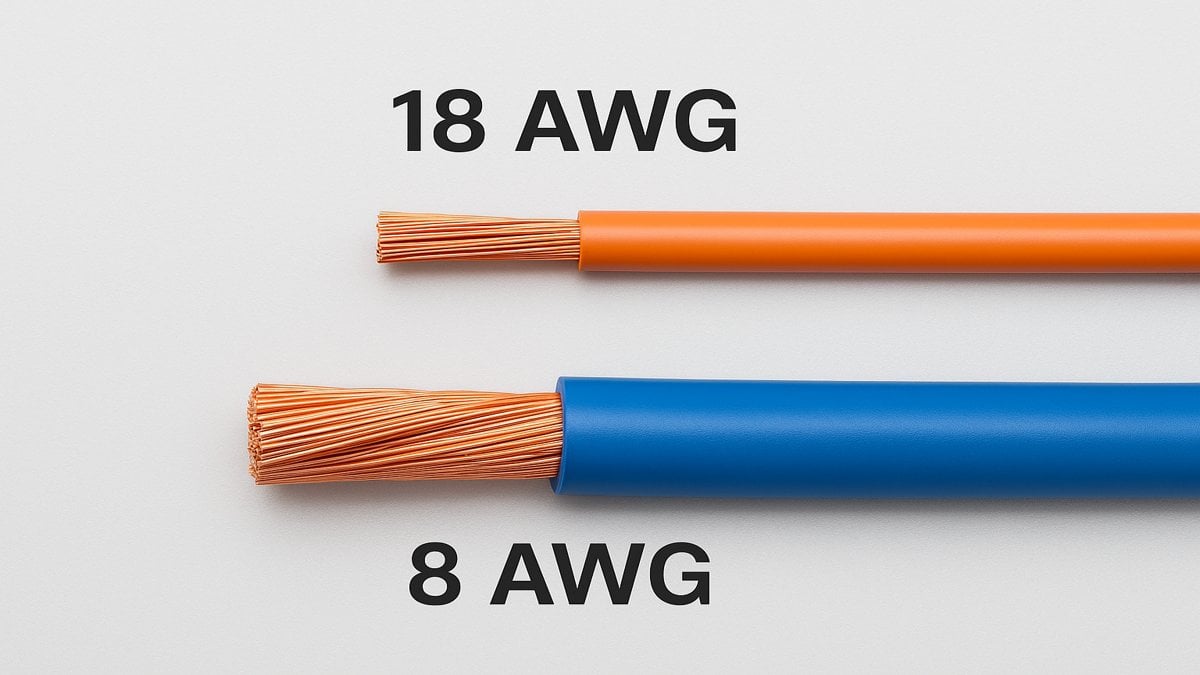

Upgrading from a 12-volt to a 48-volt electrical architecture improves overall system performance in several significant ways. As voltage goes up, current goes down. Lower current (for the same power) reduces resistive power losses by up to 16x. Lower current allows for thinner, lighter cables, and less heat is generated in wires and connectors, reducing the need for cooling or heavy insulation. Heavier, more expensive 8-gauge copper wire can be replaced with thinner, cheaper 18-gauge. High-power systems like steer-by-wire, brake-by-wire, and autonomous sensors require more voltage for stable operation so transitioning to 48V helps to “future proof” vehicle designs. Now that Tesla has “trained” some parts suppliers, we can expect to see more OEMs offering vehicles with 48-volt architectures.

800-Volt Hight Voltage Batteries

Several electric vehicle manufacturers are now offering models with 800-volt high voltage battery systems, which provide faster charging and improved efficiency compared to the more common 400-volt systems. Porsche was one of the first to adopt the technology with the Taycan, followed by its sibling model, the Audi e-tron GT. Hyundai Motor Group integrated 800-volt architecture into the Hyundai Ioniq 5, Ioniq 6, and Kia EV6, all built on the E-GMP (Electric Global Modular Platform) platform. Lucid Motors goes even further with a system that reaches up to 924 volts. Rivian, GM’s Hummer EV, and future platforms from Tesla are also embracing 800-volt technology.

An 800-volt system offers several advantages over lower voltage systems. It reduces the current needed to deliver the same amount of power, which means thinner, lighter cables can be used, improving overall vehicle efficiency and reducing weight. Faster charging is another major benefit, as some 800-volt electric vehicles can charge from 10 to 80 percent in under 20 minutes. Higher voltage systems also generate less heat, enhancing safety and durability. These improvements make 800-volt architecture especially appealing for long range electric vehicles and high-performance models. As the industry evolves, more manufacturers are expected to adopt 800-volt platforms.

Solid State Batteries

Solid state batteries have long been considered a breakthrough in battery technology because of their higher energy density, safety, longevity, and fast charging potential compared to traditional lithium-ion batteries. However, despite encouraging lab results, commercializing SSBs has been difficult. Manufacturing challenges, including sensitivity to moisture and the need for tightly controlled environments, have slowed progress. Companies like QuantumScape and Solid Power are pushing the technology forward. QuantumScape’s innovative anode-less design enhances charging speed and lifespan, while Solid Power’s use of sulfide-based separators simplifies production and cuts costs, offering a more feasible path to large-scale manufacturing.

QuantumScape’s QSE-5 battery removes the traditional anode by using lithium metal and a dendrite-resistant oxide separator. This reduces space and weight while enabling rapid charging, which is important for electric vehicles. The battery also features a clever housing system to handle swelling from fast charging. Solid Power’s sulfide-based design allows for high ionic conductivity and heat resistance. Because their materials are flexible and moisture resistant, Solid Power can use existing roll-to-roll manufacturing methods, reducing costs and helping avoid supply chain bottlenecks that have affected other SSB efforts.

Both companies are approaching commercialization. QuantumScape is preparing its “Cobra” system to produce batteries at gigawatt scale, while Solid Power has secured significant funding and partnerships, including SK Group and Ford, to scale up its own battery production. Challenges remain, such as QuantumScape’s costly high-temperature processing and Solid Power’s need to address dendrite formation. Neither company has committed to a specific launch date, but both are making measurable progress. While SSBs offer significant promise, experts suggest not waiting for them to become mainstream before switching to EVs, as current technologies already meet many consumer needs.

Please Drop Your Thoughts in the Comments Below

What are you most excited about when it comes to the future of electric vehicles?

Have you had any charging problems because you couldn’t find a charger with a plug that fit your EV?

Chris Johnston is the author of SAE’s comprehensive book on electric vehicles, "The Arrival of The Electric Car." His coverage on Torque News focuses on electric vehicles. Chris has decades of product management experience in telematics, mobile computing, and wireless communications. Chris has a B.S. in electrical engineering from Purdue University and an MBA. He lives in Seattle. When not working, Chris enjoys restoring classic wooden boats, open water swimming, cycling and flying (as a private pilot). You can connect with Chris on LinkedIn and follow his work on X at ChrisJohnstonEV.

Image sources: AI, AI, Porscha media kit

Comments

EVs are just so darned cute,…

Permalink

EVs are just so darned cute, aren't they?

Charging a 100kWh battery in…

Permalink

Charging a 100kWh battery in 15 minutes implies delivering about 80kWh in 1/4 hour or 320kW of continuous power. So a 20-stall charging station would need a 6.4MW of grid service. This is no trivial thing and it's going to take a long while to build out that much grid capacity to the point where chargers are as dense as today's gas stations.

"It always seems impossible…

Permalink

In reply to Charging a 100kWh battery in… by Bret Foreman (not verified)

"It always seems impossible until it is done." - Nelson Mandela

And all those EV’s with that…

Permalink

And all those EV’s with that old technology will be junk. How do we recycle them all?

Recycling EV batteries won’t…

Permalink

In reply to And all those EV’s with that… by Richard Loro (not verified)

Recycling EV batteries won’t be a problem because recycling plants are already reclaiming more than 90% of valuable materials from EV batteries, often profitably. Also, EV batteries typically last 5–10 years, and recycled packs are frequently repurposed in stationary energy storage before full material recovery. Fears about battery waste are overstated, given robust recycling systems and battery reuse pathways.

Range is not the problem…

Permalink

Range is not the problem. Does anybody today even look at the range of a ICE car? They do not. Gas stations are plentiful, always work, and take a few minutes to refuel. That is the problem for EVs.

Not really relevant since…

Permalink

Not really relevant since today’s EV’s are going the way of those from the early 1900’s with full rollout of Hydrogen powered engines. Multipurpose Fueling stations Petroleum/Water/Hydrogen using existing Petroleum infrastructure no need for massive power grid changes….

We keep hearing they’re…

Permalink

We keep hearing they’re coming but they’re not here yet. But boy do we need this tech asap!