According to a report by mining and investing focussed website Stockhead, Tesla will need 50 percent of the world’s current nickel supply to reach the company’s goal of 3TWh of battery production by 2030. The website makes this claim based on reports by Wood Mackenzie.and Benchmark Mineral Intelligence(BMI).

Of course, over the next 10 years, as Tesla expands its battery manufacturing, the worldwide supply of nickel is also expected to increase. But, even then, according to BMI’s analysis, Tesla will outpace the growth of nickel production, needing a whopping 26 percent of the worldwide supply of the mineral by 2030.

Given this number, BMI doubts if Tesla’s announcement can be achieved. The consultancy firm says “ultimately, from Benchmark’s perspective, the 3 TWh cell production figure is unlikely to be achieved when raw material availability and forecasted market demand are considered.”

One assumption the analysis takes to get to the 26 percent number is, what proportion of the 3TWh battery production will have a nickel-based cathode. According to Benchmark Mineral, this will be around 1.35TWh.

It is impossible to know for sure what the final proportion will be, but we can look at Tesla’s past statements to see how BMI might have arrived at this number.

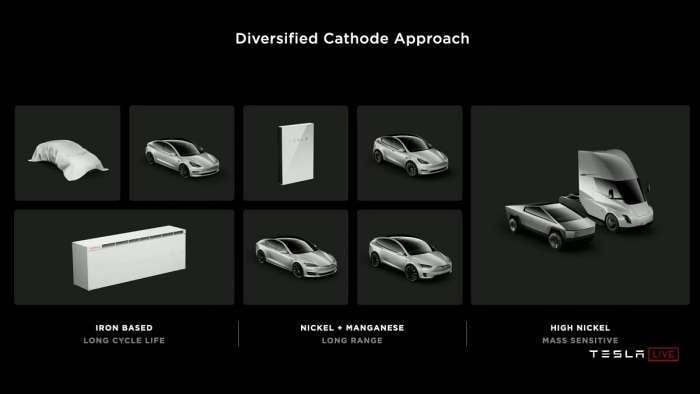

One of the announcements that came out of Tesla’s Battery Day presentation is the company’s move to pure nickel cathode. This one breakthrough on its own is responsible for a 4% range increase in the vehicles. But in the same presentation, the company said it will adopt a 3 tiered approach to its cathode plans.

These are batteries with 1) pure nickel cathode, 2) batteries with two-thirds nickel one third manganese cathode, and 3) batteries with a nickel-free iron phosphate cathode.

All 3 approaches have their advantages and disadvantages. Starting from the last one. Batteries with iron phosphate cathode have a long cycle life, higher heat tolerance and there is ample supply of iron in the world to easily meet Tesla’s growth plans.

However, like the other cathode chemistries, iron phosphate also has its drawbacks. The main one being energy density. Iron compared to a pure nickel cathode only has half the energy density.

This, when applied to the vehicles, means increased weight, lower range and makes iron impractical for use in highly weight-sensitive vehicles. Tesla plans to use these batteries for the upcoming $25,000 “Model 2” for the Model 3 and utility-scale energy storage (Megapack).

The second tier approach for Tesla is using batteries with two-thirds nickel and one third manganese cathode. The main advantage of these batteries is, they have a good energy density and allow 33% more batteries to be produced for the same amount of nickel. Tesla plans to use these batteries for medium weight-sensitive products like the Model S, X, and Y and the powerwall.

And the last one is batteries with pure nickel cathode. These have the highest energy density of all three. However, even though they have an energy density advantage, Tesla plans to use these batteries only for the Cybertruck and Semi. The reason being, limitation in the availability of nickel supply.

So given this information, the assumption the analysis probably makes is, the Cybertuck, semi, Model S, X, Y, and powerwall will account for 1.35TWh or 45 percent of Tesla’s battery production. However, it is unclear, when calculating nickel demand from these numbers, whether the analysis took into account the fact that nickel manganese batteries need one third less nickel for given battery capacity.

Nevertheless, assigning 55 percent, perhaps even less of the battery production, to Model 2, Model 3, and Megapack, makes Tesla’s ultimate need for nickel lean towards a higher estimate.

In the past Elon Musk has said half of battery cell production will go towards energy storage. And as a percentage of battery consumption, I expect the Megapack to account for the overwhelming proportion of the battery cells expected to go to energy storage. And as we said earlier, the Megapack doesn’t contribute to Tesla’s nickel demand.

Furthermore, even though, as compared to the Cybertruck and semi, Model 2 and Model 3 will use far fewer battery cells per vehicle, I still expect the 2 cars to use a big chunk of Tesla’s battery cell output. Especially considering 1) the Model 2’s 25,000 starting price will drive a lot of demand. And 2) Tesla plans to use these models in its upcoming fully self-driving ride-sharing network.

Related Story: Tesla to start producing Model 3 with cheaper iron cathode batteries this week

But having said this, no matter the underlying assumptions, where I think the BMI analysts go wrong is when they say Tesla is unlikely to achieve its goals due to mineral constraints. Given Tesla’s diversified cathode approach and the number of moves the company is already making to ensure its nickel supply, I highly doubt that mineral constraints will be the reason for the plans not being achieved.

So what do you think? Do you think Tesla will achieve its long term goals? Or do you agree with BMI’s analysis that due to mineral constraints Tesla won’t be able to achieve them? Or perhaps do you see a completely different pitfall? Let me know your thoughts down in the comments below.

For more information checkout: Vector-Space Birds Eye View Coming To Tesla Cars With Full Self Driving. Also, see Based on Elon Musk’s Tweet, a Model S Chassis and Powertrain Refresh Might Come in 2021.

Tinsae Aregay has been following Tesla and The evolution of the EV space on a daily basis for several years. He covers everything about Tesla from the cars to Elon Musk, the energy business, and autonomy. Follow Tinsae on Twitter at

@TinsaeAregay

for daily Tesla news.

Set Torque News as Preferred Source on Google

Comments

Excellent Analysis Tinsae! I

Permalink

Excellent Analysis Tinsae! I agree that is the whole reason Tesla has 3 different cathode formulas, so that if they have trouble scaling one, they can shift products to another. The Nickel needed by semis will be easily supplied by the market and most of the other products can use other chemistries if for some reason we can't scale nickle production.

Thank you very much! And the

Permalink

In reply to Excellent Analysis Tinsae! I by Paul Fosse

Thank you very much! And the nickel-manganese cathodes do still have 50 out of the 54% range increase, so it's not even like they have to make a big compromise.

That's another good point.

Permalink

In reply to Thank you very much! And the by Tinsae Aregay

That's another good point.

They will adapt and balance battery chemistry with the resources they have!

Tesla with their vertical integration will be well equipped to switch between different type of battery configurations as needed.

It is surprising analysts don

Permalink

In reply to That's another good point. by Sebastien Bouchard (not verified)

It is surprising analysts don't believe them when they spent several minutes discussing the same exact point

Nice article Tinsae. A few

Permalink

Nice article Tinsae. A few points:

1. Three is no "pure nickel cathode". They are metal oxides.

2. There are ultra high Ni content cathode candidates for next gen cathodes, but they will be multinaries (Ni + another metal + oxygen).

3. High Ni content cathodes might still have a lot of manganese in them.

4. Tesla is going to use a lot of LiFePO4 in stationary storage and shorter range vehicles. They will hit their production targets, but at worst would need to adjust the mix of LFP vs NMC vs NMA vs MNA, etc. they use.

5. My guess is that Tesla prioritizes Ni for Semi, Plaid and Roadster won't create a lot of demand for Ni and a crazy number of LFP 4680s go into 2, 3, Y and CT short range models.

Thank You Charles! And I

Permalink

In reply to Nice article Tinsae. A few by Charles (not verified)

Thank You Charles! And I agree with your by pure nickel cathode was just referring to nickel being the only active metal, in the battery day presentation Drew even said they will be using novel coatings and dopants in the cathode.