Since last March Panasonic has been looking for land in order to decide the final location of its USA factory, in which it will be producing the 4680 battery cells for Tesla. After two months of searching the Japanese company is very close to announcing the final, strategic location of this new facility. After starting production of the first test batches in Japan at the Wakayama plant - which Tesla has already received - Panasonic's intention is to get as close as possible to its most important customer in order to avoid any unexpected supply disruptions.

Japanese broadcaster NHK announced a few months ago about Panasonic's intentions to settle on US land: a company executive confirmed this information last week, adding that the location has been basically already selected. "We have been considering various options and now we are in the final evaluation phase", said Panasonic's executive director for energy, Kazuo Tadanobu. The two locations that potentially had the most possibilities were Kansas and Oklahoma – both very close to Austin – where, as everybody knows at this point, Tesla opened its latest Gigafactory and which has also become the company's headquarters after its CEO, Elon Musk, actually moved to live there.

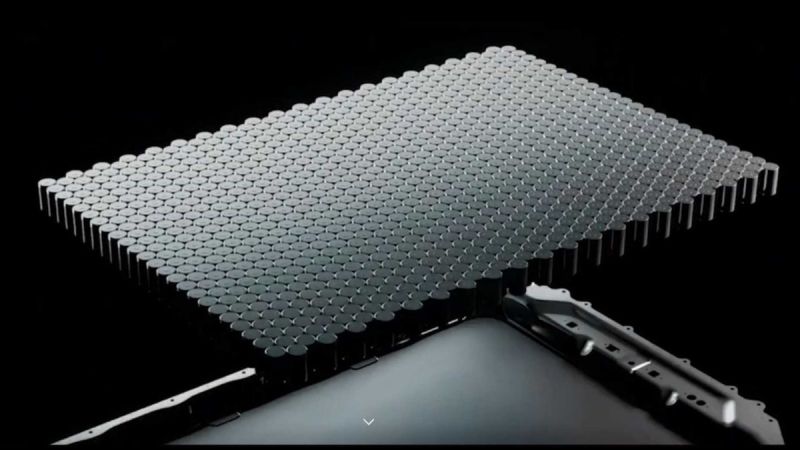

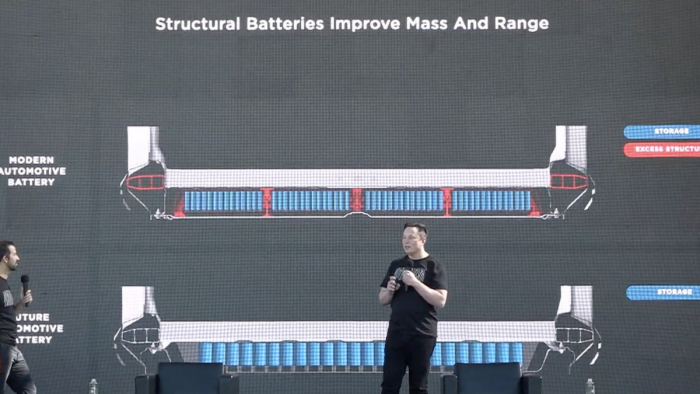

As per a Reuters report, and during the same press conference, Tadanobu announced to analysts and investors that the company has already sent Tesla the first samples of the 4680 cells manufactured - for the time being - in Japan. Panasonic's new 4680 format battery cells (46 millimeters wide and 80 millimeters high) are about five times larger than those it currently supplies. With the format change, Tesla could reduce production costs and actually increase the range of its electric cars, thanks to a better use of packaging techniques and to the advancement of cell chemistry that basically uses nickel, cobalt and aluminum as main cathode materials. Panasonic claims that its ability to store energy is superior, which in turn can reduce battery costs by up to 50%.

Mass production of the new battery cells will begin at the Wakayama plant in western Japan in March next year. Then, once a location is finally selected, mass production of the new 4680 batteries will move to the United States where it will start a year later, in March 2024.

Tesla and Panasonic have been exclusive partners for more than a decade, operating the Nevada Gigafactory. However, with the opening of the Shanghai Gigafactory, Tesla turned to CATL and LG Energy Solutions as new suppliers. Last summer CATL announced its intention to expand its partnership with Tesla in China and become its largest battery supplier; the company aims to supply half of the battery cells Tesla uses globally.

Back in 2010, a full two years before Tesla introduced the Model S, Panasonic bought 1.4 million shares of Tesla stock at a bargain price. In March last year, it sold its stake in Tesla, which at the time was worth about 400 billion yen ($3.61 billion). Despite this financial transaction, Panasonic assured that it would not affect at all its business partnership with Tesla and that the two companies would perfectly continue to produce batteries in the USA.

Source: reuters

All images courtesy of Tesla Inc.

Nico Caballero is the VP of Finance of Cogency Power, specializing in solar energy. He also holds a Diploma in Electric Cars from Delft University of Technology in the Netherlands, and enjoys doing research about Tesla and EV batteries. He can be reached at @NicoTorqueNews on Twitter. Nico covers Tesla and electric vehicle latest happenings at Torque News.

Set Torque News as Preferred Source on Google