Tesla Will Use Multiple Form Factors For Batteries

Many people think that LFP batteries will be in the 4680 form factor. This is not true - at least not yet. They are going to be the 2170 form factor and those will still come out of Fremont and Giga Berlin (assuming Giga Berlin ever comes online).

Elon has said on 3 occasions I can think of, that LFP will not use the 4680 form factor. I can understand why. Tesla have spent all this time, capital, resources in researching the ultimate form factor for their batteries and they won't use it for LFP? Here's why:

One of the most important elements of the new battery was that it must have a good enough energy density to get a decent range for Tesla semi trucks. If we can't power all vehicles electrically, then getting off fossil fuels won't work so well.

There is a lot riding on these batteries. The other thing that was needed is a lot of range. Tesla have discovered an application for vehicles that may mean the life usage increases maybe 10 fold, with a vehicles entering a robotaxi network.

Tesla needed a special battery that could handle one million miles without too

much degradation. Along with manufacturing techniques to get the cost of the battery down significantly. This battery was so important. It truly is the biggest break-through technology to date that will take transportation electric.

Engineering The Million Mile Battery

I understand from a manufacturing or engineering perspective how much easier and better life would be if all Tesla batteries were the same size and form factor, which of course would makes things easier to manage. Is Tesla's mission to accelerate the transition in a clean and orderly fashion, or was it to do it as a fast as possible? Tesla are currently working with all sorts of form factors currently, and managing to do well.

This is not what is holding the company back. If growth of Tesla was being stunted by the fact they had to make so many different battery packs for all the different form factors, then maybe it would a good idea. But that is not what will hold back Tesla, it's going to be the actual battery supply. Tesla want as many batteries as they can possibly get and there still isn't enough! It doesn't matter if its prismatic or cylindrical form factor.

Tesla are adapting already to the different form factors. If they can continue to adapt to more, then it will mean they simply have that many more batteries available to them. It makes sense, but why can't Tesla make all their other batteries a 4680 form factor. In other words why can't Tesla make their LFP batteries 4680?

The 4680 batteries are designed around what is best for the nickel cathode designed battery. The entire battery is designed around that specific chemistry, but not only that, it's also designed around the desired application. What was the desired application of the 4680 nickel cell?

It was to power a long range semi truck, be suitable for robotaxi miles, and get the costs down. The battery cell was designed to optimize these qualities. The problem is nickel is too scarce for the number of batteries needed to transition the world to sustainable energy. But what about LFP batteries? LFP batteries are already a lot cheaper. I think the million mile battery will be an LFP battery.

LFP Batteries

LFP batteries are lithium-iron-phosphate batteries and are a much better choice for batteries for the future, due to the abundance of iron in the world. Therefore, maybe there will be less compromises on other elements, in trying to get the prices down.

The issue with LFP is the energy density. LFP batteries lack in density and will thus be a form factor that generates the greatest energy density for LFP. Likely using some of the chemistry we saw on battery day, namely the silicon used in the anode, thus increasing the lithium-ions you can store in the battery.

Honestly, if Tesla just made a small dent on battery efficiency with LFP, and managed to improve ranges by 10%, that would be such an insane break through. The Model 3 standard range with 300 miles. That would be an immense win for Tesla and EVs.

Yet the cost, well probably another $4,000 saved from CATL LFP to Tesla LFP. But CATL can't make enough anyway. This would also mean that Tesla's biggest selling product would now be possible. It doesn't take much improvement until we see big jumps and more products become feasible. This would mean that Tesla could offer a decent range in a standard range Model Y, possibly above 260 miles of range.

This will be Tesla's best selling product for sometime, maybe ever, at least their best selling vehicle. I can't see any other car will outsell that. Bearing in mind that there is no $25,000 Tesla on the way. The profit margins on an LFP Model Y sold in the major markets, would be insane, and they would sell so well.

I know it may be a mess having all sorts of different batteries, but it really is ok. That's Tesla's problem to deal with for whatever issues there are managing different form factors. But I imagine they will keep it as tidy as possible, and that the batteries are somewhat consistent e.g. all standard ranges from China will continue to use CATL LFP, but all other standard ranges use Tesla's LFP.

Structural Batteries and Energy Density

Structural battery packs are the future, which is why the 4680 batteries are so good. Well not many people seem to know this, but Tesla are already using structural battery packs with their LFP batteries, in the standard range versions. That is part of how Tesla were able to do such a good job with LFP by getting the weight down, making them structural.

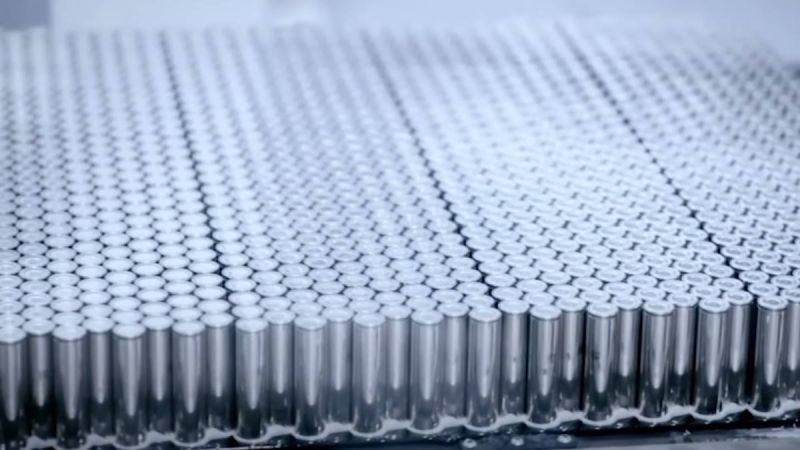

Obviously though any batteries Tesla make in-house for vehicles will be structural. All the batteries Tesla make in-house will be in cylindrical form. I don't think Tesla has a choice as the manufacturing speed is just that much faster than anything else and Tesla needs to make a lot of batteries.

I also heard that cylindrical is the most difficult to work with for the battery manufacturer, but the easiest to work with for the car manufacturer. What about the batteries Tesla makes that are not for vehicles, such as for the energy business? We have a different application here again, we would likely require a different specification battery.

What's the major difference between batteries used for transport -vs- energy? The difference is energy density. Energy storage is not continually moving, it's weight is of little consequence, as is its energy density. Therefore I think Tesla will make another form factor specifically for energy.

What qualities are we going to be looking for when it comes to energy? Abundance is the first key as a huge number of batteries will be needed. We are very likely talking an iron cathode. But we also want these batteries to be cheap, and as they don't need to be energy dense, then the cost should come down a lot. Tesla's energy business is still not profitable, because Tesla are using batteries that are designed for EVs, in energy. This needs to and will change.

No one has really designed a specific volume production battery for energy storage yet. So two things - abundant and cheap. Tesla could be looking at sodium-iron batteries instead of lithium, as sodium is cheaper and more abundant. So we might see a whole new chemistry there again when it comes to energy. We'll have the latest chemistry we recently heard on the earnings call, that Tesla are going to potentially launch.

A manganese based cathode. This is actually very exciting, as there is enough manganese to make a lot batteries for vehicles. It also might serve as the sweet spot, a cost closer to iron, yet still not far off the energy density that nickel can generate, yet manganese is more abundant. I think Tesla could potentially make long range Model 3s and Model Ys using these manganese batteries. That's how energy dense they might be.

The scarce nickel might be used only for semi trucks and the Tesla Bot. All these chemistries and battery forms are exciting though... Still, it will come down to how Tesla can manufacturer them. We need them manufactured at a very fast speed. There are a lot of batteries to make. But with an assortment of batteries and technologies available from Tesla, it wont take long until they are the largest battery manufacturer in the world - perhaps by 2025.

For the foreseeable future, Tesla will keep their own batteries because they need more than anyone else, and they are more valuable to Tesla than to anyone else. There will be some great products coming from these batteries. I expect a battery day announcement again sometime this year. It might tie in with the annual shareholder meeting too. So maybe sometime in October. I think we'll hear about batteries for the semi, Cybertruck, and even the Roadster!

Will Tesla continue to use multiple form factors? Will they ever use a single form factor?

Leave your comments below, share the article with friends and tweet it out to your followers.

Jeremy Johnson is a Tesla investor and supporter. He first invested in Tesla in 2017 after years of following Elon Musk and admiring his work ethic and intelligence. Since then, he's become a Tesla bull, covering anything about Tesla he can find, while also dabbling in other electric vehicle companies. Jeremy covers Tesla developments at Torque News. You can follow him on Twitter or LinkedIn to stay in touch and follow his Tesla news coverage on Torque News.

Set as google preferred source

Comments

I predict structural

Permalink

I predict structural batteries will go beyond cars