Did a five-minute bolt-on part just turn a powerful Ram Rebel into a limping disaster? Read on to find out the surprisingly common reason for Ray's engine failure and how Ram owners can avoid it.

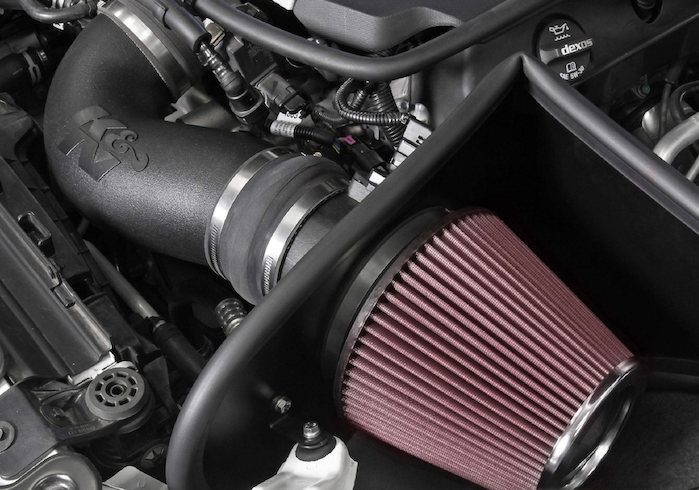

While researching the common pitfalls of aftermarket cold-air intakes on performance trucks, I came across Ray Wilson's alarming post in a Ram Rebel owner's group. Ray hoped his new K&N filter would boost performance, but the engine light came on immediately, and a severe speed restriction turned his exciting upgrade into an instant mechanical headache. His experience perfectly illustrates a potential and often misunderstood risk when modifying modern vehicle air systems.

Ray Wilson on the Ram Rebel Owners Facebook page says:

"I installed the K&N filter today. And on one test drive, it threw an engine light error and wouldn't go past 15 mph. It's crazy, all I did was put the filter on. Do I need to reset the code with a diagnostic machine?"

Ray's story is a classic case of expectation meeting reality—and losing badly.

He was thrilled to install the new cold air intake, attracted by the promise of more power and a better sound. But the update to the check engine light (CEL) and the truck refusing to go past 10 or 15 mph (a condition known as "limp mode") is where the dream abruptly ends. His question, "Do I just need to reset the code with a diagnostic machine?" is the first, crucial point we need to address.

My immediate answer, based on years of working with truck manufacturers and covering these scenarios as a senior writer for Torque News, is: No, a simple code reset is not the solution. It's a temporary Band-Aid that ignores the underlying and highly specific mechanical problem that has plagued the aftermarket performance community for decades. We are not just dealing with a simple electrical glitch here.

This sudden, severe loss of power isn't a random occurrence; it's a calculated protection mechanism built into your Ram's computer, the Powertrain Control Module (PCM). The PCM is reading a critical fault that directly affects the engine's air/fuel mixture, triggering the limp mode to prevent catastrophic engine damage. The irony is that the pursuit of a small horsepower gain led directly to zero horsepower.

Why Did This K&N Filter Cause Catastrophe?

The most probable culprit in Ray's situation, and the reason for the engine code that put his Ram into limp mode, is the Mass Air Flow (MAF) Sensor.

Modern engines, especially those like the Hemi found in the Ram Rebel, use a very sensitive MAF sensor placed right in the air intake tube between the air filter and the throttle body. Its job is hyper-critical: it measures the precise volume and density of air entering the engine. This data is essential for the PCM to calculate the correct amount of fuel to inject.

Here is what went wrong, and why this is a common issue when people attempt a K&N cold air intake installation:

- Over-Oiling: K&N filters are cotton-gauze filters that should be oiled after cleaning. If the filter is over-oiled during manufacturing or maintenance, the excess red oil can aerosolize (turn into a fine mist) under the engine's intense vacuum.

- Contamination: This oil mist then contacts the MAF sensor's fragile platinum wires or heating elements. This residue coats the sensor, insulating it and causing it to deliver faulty, low readings to the PCM.

- Limp Mode: When the PCM receives a reading indicating a significant airflow discrepancy, it thinks the engine is starving for air when it isn't, and it concludes that a critical failure has occurred. To save the engine from running dangerously lean, it instantly throws a code (likely P0101 for MAF sensor performance). It activates the dreaded limp mode, sharply limiting RPM and speed to protect the drivetrain.

As a reporter who focuses on advice for my readers, I have often warned enthusiasts about modifications, especially missteps with critical sensors.

My Recommendations

Ray and any other Ram Rebel owner experiencing this need to take a two-pronged approach. Do not drive the truck, and absolutely do not reset the code and try again until the sensor is cleaned.

1. Immediate Action: Salvaging the MAF Sensor

The MAF sensor must be cleaned immediately to restore proper airflow readings.

- Disconnect the Battery: Disconnect the negative battery terminal for at least 30 minutes to ensure all system capacitors are discharged. This clears the temporary memory the PCM holds, effectively resetting the error codes without using a diagnostic tool.

- Remove and Clean the MAF: Carefully remove the MAF sensor from the air intake tube. You must use a cleaner specifically labeled as MAF Sensor Cleaner. Do not use brake cleaner, carburetor cleaner, or any other harsh chemicals; they will damage the sensor. Spray the element thoroughly and let it air dry completely (do not touch the sensor element).

- Address the Filter: If the filter is indeed over-oiled, you may need to clean and re-oil it correctly, using minimal oil. Better yet, swap in a known good, dry filter for testing.

2. The Long-Term Fix and Future-Proofing

If your MAF sensor is truly ruined, replacement is necessary. However, the greater issue is ensuring your long-term engine health and protecting your wallet. This leads us to a necessary discussion about warranty protection. While the Magnuson-Moss Act generally protects consumers, the onus is on you, the owner, to prove the aftermarket part did not cause the failure. In Ray's case, the failure occurred immediately after the install, making a warranty claim for the MAF sensor highly problematic.

To prevent this from becoming a recurring issue:

- Strict Oiling Protocol: When cleaning and re-oiling your K&N filter, use the absolute minimum amount of oil necessary. Hold the filter up to the light; if you see any wetness, it's too much. The process should leave the cotton gauze just barely tinted pink/red, not visibly saturated. This is critical for preventing Mass Air Flow sensor issues in modern Hemi engines.

- Consider Dry Filters: For owners concerned about oil mist, consider switching to a high-flow dry filter. While they may not offer the same 'numbers,' they eliminate the contamination risk.

- Understand the Codes: Ray's Ram is likely experiencing a code that points to a lean condition (like P0171/P0174) or a MAF sensor performance issue (P0101), which are often triggered by a contaminated MAF sensor, causing the PCM to incorrectly try to compensate for what it perceives as too much air.

By following these procedures, Ray can get his Ram Rebel out of limp mode after aftermarket air filter installation and back on the road safely, without the need for expensive dealer diagnostics that might flag the modification.

What Owners Are Saying

The confusion around cold air intakes and check engine lights is universal. Here is what other owners are sharing across the web:

"I had the same issue on my Challenger. Ran fine for a week, then P0101 and limp mode. Dealer technician said they see it all the time with K&N, and the solution was cleaning the MAF sensor with CRC cleaner and switching to a dry AEM filter."

"This is why you always buy MAF sensor cleaner BEFORE you buy the intake. I was paranoid about the Ram Rebel's check engine light after installing the K&N cold air intake, so I followed a low-oil tutorial and avoided the problem entirely. Don't touch the sensor with your hands!"

Key Takeaways for Performance Enthusiasts

- The Problem is the Oil: The limp mode is virtually always caused by MAF sensor contamination from over-oiling the cotton gauze filter element.

- Avoid the Dealer: A dealer visit risks having the modification flagged, potentially leading to questions about potential warranty issues.

- MAF Cleaner is Non-Negotiable: Only use dedicated MAF Sensor Cleaner. Any substitute is engine-hazardous.

- Prevent, Don't React: Use a minimal amount of oil on reusable filters, or switch to a dry synthetic filter to avoid the issue entirely.

- Reset Procedure: Clearing the code and exiting limp mode is best achieved by disconnecting the battery for 30+ minutes after cleaning the sensor.

In The End

Ray Wilson's experience is a valuable lesson for the entire Ram community: when modifying your vehicle, always understand the immediate downstream effect on critical sensors. The fix is often simply a thorough cleaning of the MAF sensor, but the risk is significant, which is why proper installation and maintenance of high-flow air filters are crucial to the performance and reliability of your Ram Rebel.

How About You?

If you've experienced this specific issue with a contaminated MAF sensor on your Ram, Dodge, or Jeep, what specific cleaning method did you use, and did you switch to a dry filter? Click the red Add New Comment link below and let us know.

I'm Denis Flierl, a Senior Torque News Reporter since 2012, bringing over 30 years of automotive expertise to every story. My career began with a consulting role for every major car brand, followed by years as a freelance journalist, test-driving new vehicles, equipping me with a wealth of insider knowledge. I specialize in delivering the latest auto news, sharing compelling owner stories, and providing expert, up-to-date analysis to keep you fully informed.

Follow me on X @DenisFlierl, @WorldsCoolestRides, Facebook, Instagram and LinkedIn

Photo credit: Denis Flierl via RAM, K&N