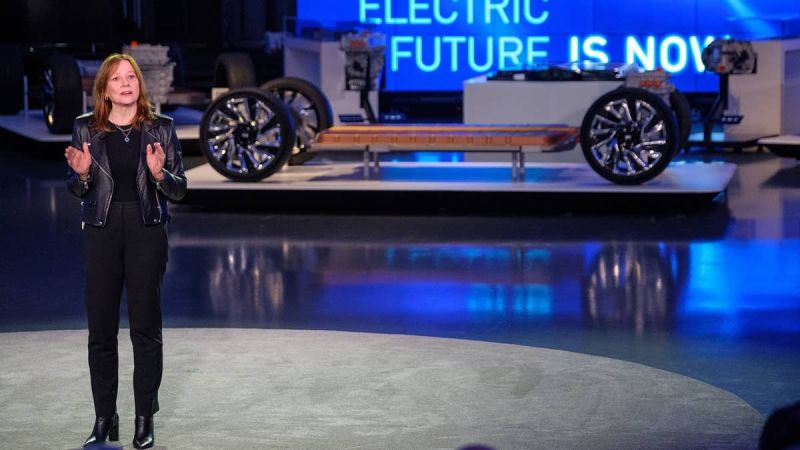

In 2017 GM’s CEO Mary Barra made bold claims for the company, saying that that GM was making a huge commitment to EVs and that they would launch a new family of EVs in 2021, and offer 20 new EVs by 2023. Unfortunately, GM has not built any new (U.S. sold) EVs since then other than the Bolt, and the lack of any solid EV news has been looking bad for GM. But they did recently tease the upcoming GMC Hummer EV pickup/SUV, and now they finally had a big reveal of their upcoming electric vehicles at their recent EV Day.

EV Day and the Ultium battery platform

EV Day was a presentation to the press and GM investors showing prototypes of upcoming GM EVs, and they revealed some real information about GM’s EV roadmap moving forward. One big piece of news was Ultium. No, it’s not a new Marvel superhero. It is GM’s global EV platform with new electric motors and improved battery packs. GM is taking a modular approach that allows for pouch batteries and also prismatic cell batteries.

The new pouch batteries (jointly developed with LG Chem) which are coming out initially are supposed to have much lower cobalt than before, but they will still have 60% better energy density when compared with today’s Bolt batteries. GM says that soon the new battery price will be down to $100 per kW (cell cost), and it will drop even more over the next few years. Ultium storage capability will range from 50 to 200 kWh, which could potentially provide a range up to 400 miles (644 km) or more on a full charge.

The Ultium platform will have an integrated BMS ()battery management system) to maintain and charge the battery. It will be an 800V system (like Porsche’s Taycan) that potentially provides up to 350kWh charging. EV motors designed in-house will support FWD, RWD, AWD, and performance versions. And for the top EV models 0 to 60 mph acceleration could be as low as 3 seconds. Cadillac had planned on revealing their upcoming Lyric EV crossover that will use the Ultium chassis on April 2nd, but that has been postponed due to national health concerns. GM had earlier teased the Hummer EV, and it’s reveal is still planned for May 20th, so far.

GM and LG Chem build a battery factory

Late last year, GM announced that they were going to spend 2.3 billion dollars to build a large battery manufacturing facility in Lordstown, Ohio. It will supposedly have a production capacity of more than 30 gigawatt hours per year in batteries, but it may not actually be producing batteries until 2022. LG Chem is one of the world’s largest lithium-ion battery manufacturers, currently supplying batteries to automakers like VW, Mercedes-Benz, and Jaguar. But recent shortages in automotive batteries caused Jaguar to pause production on it’s iPace EV, and Audi to stop building it’s E-Tron CUV. Hyundai also faced battery production shortfalls last year that limited EV production on Kia EVs and they held off on releasing the new Soul EV. Similarly Mercedes delayed the U.S. introduction of it’s new EQC EV crossover another year.

VW’s MEB Platform

Like GM, last year VW similarly outlined their own MEB global EV chassis/motor/battery platform that will be the basis for several upcoming EVs. VW said that they have plans to build and sell over 300,000 EVs this year, with over 1 million EVs to be produced by 2025. VW plans to first use of their MEB platform for their upcoming ID.3 EV model. It is due out late this summer (in Europe only). VW is also planning to release the ID.4 crossover as a global model (including the U.S.) due in 2021. VW has partnered with several Chinese battery manufacturers, and is working to build a couple battery factories in China in addition to current battery production plans in Germany.

Tesla is Not Sitting Still

Tesla is currently the only automaker that only sells EVs in large production volumes. They were the first to produce EVs with long range capabilities and their internal goals are to produce batteries and motors that are 2-4 years ahead of their competition. But with huge automakers like VW, Hyundai, GM, and Ford that are starting to seriously build EVs, they have vast resources to apply to EV technology. I believe that Tesla’s biggest advantage is that ALL of the biggest legacy automakers have made 100% of their profits from selling ICE (internal combustion engine) vehicles, and dealers have made millions maintaining them. So other than government mandates for less polluting vehicles and improved fuel economy, there are few incentives for the legacy automakers to build competitive EVs. And Tesla enjoyed many years with little EV competition. But now with the big dogs entering the EV game, Tesla needs to innovate more to keep it’s lead.

Tesla’s Panasonic Connection

Like GM and LG Chem, Panasonic and Tesla had teamed together and Tesla built the Gigafactory 1 in Nevada, and inside the factory Panasonic manufactures the batteries and delivers them to Tesla for use in their automobiles and Powerwalls. The Giga Nevada factory is producing close to 30 gigawatt hours per year (like the proposed LG factory). Which should be enough for the successful Model 3, and the new Model Y as well as the Model S and X.

Thing are a Changin’

But since China is easily the world’s largest EV consumer it made sense for Tesla to build a Gigafactory (#3) to build their cars in China. They also made a deal with LG Chem (yeah that same LG Chem) to make Model 3 and Model Y battery packs in China. Initially, the first Chinese Model 3s used battery packs (Panasonic) from the Giga 1 in Nevada, but future batteries for China vehicles will likely be all built in Giga 3 in China. And use batteries from LG Chem, Panasonic, and China’s BYD and CATL. And there is the built in production capability to make all of Tesla future batteries in their China factory.

But the twist is that Tesla might be manufacturing the batteries themselves. Inside the U.S. Gigafactories, Panasonic operates like an independent factory where they hand off completed batteries to Tesla for use in their vehicles. But Panasonic’s battery production was barely keeping up with the booming sales of the Model 3 last year, and with Model Ys now being built, there needs to be more battery capacity. So Tesla is most likely going to start building their own batteries, and they will be using some new technology in their production.

Maxwell technologies

It was over a year ago when Tesla completed the acquisition of the San Diego-based ultracapacitor and battery company Maxwell Technologies for over $200 million. The biggest reason was that Maxwell had developed a dry electrode technology that will simplify battery production, dramatically lower production cost and time, and increase battery life and energy density. Late in 2019 Elon Musk announced that they would be producing a “1 million mile battery”. Considering that today’s Tesla batteries are supposed to be good for 300K-500K miles of use, that is quite an achievement. Maxwell could also provide ultracapacitor technologies for hybrid battery systems that take advantage of the best capabilities of Lithium Ion batteries and ultracapacitors together.

Cheaper batteries for China cars

Another item that has come up recently is the probability that Tesla will build a lower cost prismatic battery with CATL in China to lower battery costs there even more. Tesla’s Panasonic batteries are cylindrical, and have good energy density. But potentially Tesla could save as much as 25% on the battery pack cost using a prismatic battery pack. CATL’s (lithium iron phosphate) LFP battery chemistry uses no cobalt and has better resistance to heat and charging. The downsides are lower energy density and the prismatic case design is harder to cool than cylindrical or pouch cells.

Tesla Battery Day

I believe that Elon is going to drop a huge bomb on the EV industry in April in their upcoming Battery Day. The news will probably confirm the Tesla battery information that I outlined above, but there could be an even bigger surprise beyond the million-mile battery and dry electrode technology. Rumors of graphene and solid-state batteries have been swirling around Tesla for a while now, and one point sticks in my mind. When the new Tesla Roadster and Semi were announced, the initial specs were given which not only showed an amazing 8.8-second ¼ mile acceleration capability, but they said that it would have a 200kW battery (same capacity as GM’s biggest Ultium pack), but with a 620-mile range (as opposed to GM’s 400-mile range).

Now considering that Tesla’s current 100kW battery is rated at 390 miles of range in the Model S, doubling the size could easily produce 620 miles of range. But thinking practically, I cannot see a 2200lb/200kW battery pack in the relatively tiny Tesla roadster. And I am hoping that means that they have been able to perhaps double the energy density of their new batteries to provide the 200kW in a smaller battery pack. Whatever the Tesla battery announcements are, we will find out very soon.

Even though I expect to see the biggest EV technology leaps of 2020 to come from Tesla, I am totally pleased to hear a real confirmation of GM’s EV progress with several new electric vehicles coming out in the next few years. Rivian will make a big splash this year when they start building their impressive R1T EV pickup. Ford will produce their Mach-E this year ushering a new age of competitive EVs that aren’t just compliance cars. And VW will hopefully be showing off their ID.4 crossover this year, even if production isn’t likely this soon.

What do you think will be the breakthrough battery and EV technologies for 2020?

Also see: Tesla May Hold a Virtual Battery Day and Show a Car With New Battery in Person.

About the author: Dean McManis and an electric vehicle advocate and frequently reports EV stories at Torque News. Dean can be reached on LinkedIn.

Set as google preferred source