Melbourne-based Syrah Resources Ltd. will supply Tesla with graphite anode material for an initial four years, with an option to buy additional volumes subject to further expansion at Syrah’s Vidalia plant, the Australian company said in a statement. The Louisiana facility is planned to process graphite from Mozambique to become the first U.S.-based source of graphite anodes for the country’s fast-growing electric vehicle and lithium-ion battery manufacturing industry, as per a report on yahoo finance - James Thornhill.

According to the report, the deal with Tesla would help underpin a final investment decision on the production plant expected next month and help secure local supply, Syrah’s Managing Director Shaun Verner said by telephone. China produces almost all of the graphite used in producing materials for anodes, demand for which is forecast to increase fivefold by the end of the decade, according to BloombergNEF.

Syrah is aiming to be the first major integrated ex-China producer of natural graphite Active Anode Material (AAM) that is battery ready for electric vehicles. Syrah's project site in Vidalia has all the key requirements for large scale AAM production, like access to key utilities (Water/Gas/Power) and water and air discharge compliance obtained; options to expand facility size, direct barge/port access to Mississippi river, and supportive government relations; access to key consumables (HF, HCL, Caustic) and capable workforce, as per the information available on its website.

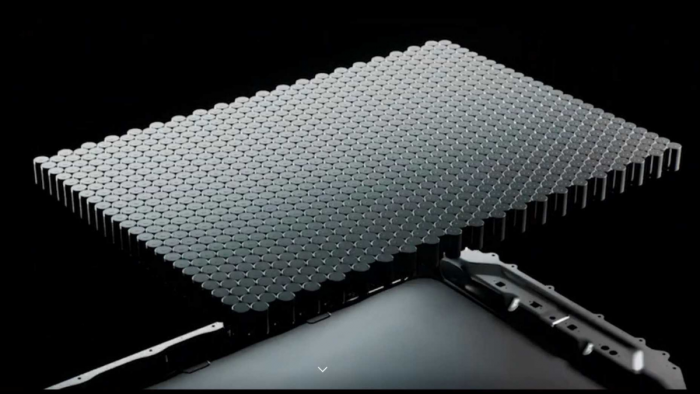

Syrah plans to be vertically integrated and undertakes the following value added steps from mining, in Balama, to produce AAM: a) natural graphite concentrate (-100 mesh fines material) is transported from Balama Graphite Operation to Vidalia; b) natural graphite is then shaped into a spherical shape and purified to produce an anode precursor material; c) precursor material is then coated and heat treated to produce a finished AAM.

Development at Vidalia to date has been focused on establishing production lines that are of sufficient scale to demonstrate Syrah’s capability to supply ex-Asia markets with AAM that: has equivalent or superior physical and electrochemical properties to currently available material; is cost competitive with incumbent supply (currently 100% based in Asia); provides an environmentally superior alternative to existing AAM supply; and is capable of supplying growing US and European markets.

The Balama graphite operation in Mozambique is a globally significant natural graphite resource. Balama's 50+ year mine life, and high reserve grade (16% total graphitic carbon) will enable the Company to participate in the long term growth of the electric vehicle industry. Located in the Cabo Delgado Province, Mozambique, the mine is a simple open pit mining development, low strip ratio, with conventional processing - includes crushing, grinding, flotation, filtration, drying, screening and bagging.

The Plant capacity is 2Mtpa ore throughput, ~350ktpa graphite concentrate, and the product yields 94% to 98% fixed carbon graphite concentrate; the water for Balama is supplied from the Chipembe Dam which has a capacity of approximately 25 million m3 and is located 12km away.

Going back to Yahoo finance, it also mentioned that, given the fact that China produces almost all of the graphite used in producing materials, "…such concentration poses a risk to rivals looking to build domestic battery supply chains, such as the U.S. and Europe.”

Earlier this month, Tesla asked the U.S. government to waive tariffs on graphite from China, saying it couldn’t access enough of the material from elsewhere. Vidalia’s initial 10,000 ton-a-year production rate would be able to supply about 3% of U.S.-based battery demand by 2025, according to industry estimates cited in a Syrah presentation.

"… the top battery and EV manufacturers are scouring the planet to secure supplies of battery materials such as lithium, cobalt, nickel and graphite as the global push toward a greener future fires up demand at a time of constrained supply exacerbated by the pandemic. Tesla in July struck a major nickel offtake deal with BHP Group, the world’s biggest mining company", the report on yahoo finance continued.

Not surprisingly, Syrah’s shares jumped as much as 35% on Thursday following the announcement - the most since March 2020 - before being placed on a trading halt pending a statement from the company on further information regarding the announcement, according to yahoo finance.

You can get more information here: yahoo finance; and get details on the Syrah developments here.

All images courtesy of Tesla Inc.

Nico Caballero is the VP of Finance of Cogency Power, specializing in solar energy. He also holds a Diploma in Electric Cars from Delft University of Technology in the Netherlands, and enjoys doing research about Tesla and EV batteries. He can be reached at @NicoTorqueNews on Twitter. Nico covers Tesla and electric vehicle latest happenings at Torque News.

Set Torque News as Preferred Source on Google