According to the Center for Compact and Efficient Fluid Power (CCEFP) website, ccefp.org, the image shows Test Bed 3 for highway vehicles. Adapting to trucks only seems natural.

CCEFP research is already creating hydraulic and pneumatic technology that is compact, efficient, and effective. The goals of the Ford project, for example, are to explore the potential for hydraulic power trains to drastically improve fuel economy in personal transportation, to identify the technological barriers to achieving those goals, and to propose solutions.

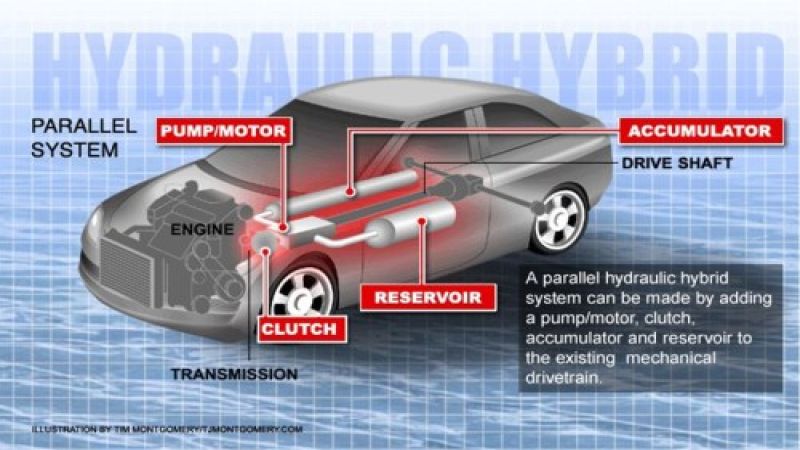

Contrary to popular belief, this proves there’s more than one way to hybridize an automobile or a truck. Hybrid vehicles, normally thought of as an IC engine with a parallel electrical motor, can also include a hydraulic motor system in conjunction with a pressurized accumulator for energy storage; thus enabling power regeneration from braking.

Fact is, electrical systems have not been as efficient at electrical storage, especially for larger vehicles, because lithium-ion batteries do not dissipate and discharge energy at very high rates. That is why extensive research is being done to develop ultra-capacitors. More on that subject in my upcoming article.

Now, consider the fact that an accumulator is a mechanical version of a capacitor that stores electrons. An accumulator stores energy in a tank by compressing a free piston with a bladder backed by a large spring or a pressurized gas.

It is the high-power density of hydraulics that makes them attractive as an alternative hybrid technology. It’s more than theory, too, that they should be able to provide both high mileage and high performance. However, in order to realize their full potential for small vehicles, hydraulic hybrid drive trains must overcome limitations in component efficiency, energy density and noise.

Out of the three possible architectures for hybrid drive trains, including series, parallel and power split, it is the parallel and power split that make energy regeneration possible for vehicle propulsion. A series drive merely transmits all power to the wheel through fluid power, much like a fork lift. A parallel architecture augments the engine with a pump/motor, and that allows a much smaller IC engine to be used, thus lower emissions.

The power split architecture, however, combines the positive aspects of the series and parallel drive train. A mechanical shaft is available to transmit power to the wheels, but the alternate fluidic path can also be used to achieve full engine management.

Regarding the Ford/Folsom collaboration, the hydrostatic transmission has been built at Folsom Technologies and is currently in testing. The unit, originally designed as a continuously variable transmission, is to be fitted with an accumulator to create an output-coupled, power split hybrid drive train architecture.

According to the CCEFP website, simulation indicates a 50% improvement in fuel economy relative to a conventional drive train. Adding a high pressure accumulator and two valve outlets to the transmission will make regenerative braking and additional engine management possible.

Conclusion

It wasn’t that long ago that Sergio Marchionne of Fiat/Chrysler Group made a statement with the EPA that it was studying the feasibility of a hydraulic hybrid for a future mini-van.

It also wasn’t that long ago that Scuderi Group announced its development of an air hybrid using its split-cycle engine technology.

Fact is, it’s not the hydraulic portion that makes the non-electric hydraulic hybrids feasible, but compressed air for the hydraulic system’s accumulator.

So, too, is compressing air for the Scuderi air hybrid in a storage tank, because it is already one-half of the split-cycle process. Furthermore, it’s scalable and likely to be less costly.

-----------------------

About the Author: After 39 years in the auto industry as a design engineer, Frank Sherosky now trades stocks and writes articles, books and ebooks via authorfrank.com, but may be contacted here by email: [email protected]

______________________________

Additional Reading:

Marchionne announces EPA hydraulic hybrid technology for next mini-van

Air hybrid technology key to 2016 and 2025 truck fuel economy

GMC Terrain uses active noise cancellation to improve gas mileage

NGVAmerica expects growth of natural gas in vehicles to continue in 2011

Dual fuel upgrades on the rise for heavy trucks

Will NHTSA and EPA proposed rules usher America into the age of natural gas?

GE demonstrates dual battery system as optimal for heavy vehicles

Set Torque News as Preferred Source on Google