U.S. Energy Secretary Steven Chu announced the three winning startup companies for this year's first annual America's Top Energy Innovator challenge, hosted by the Department of Energy and to be showcased at the 2012 ARPA-E Energy Innovation Summit at the end of the month. The winners were chosen by expert review and public vote from 14 startups who participated.

When the competition began, 36 companies entered for participation and were narrowed to 14 after signing of option agreements allowing licenses of advanced technologies developed and patented for any one of the DOE's 17 National Laboratories and the Y-12 National Security Complex.

Those winners include three exciting technologies, all of which will have huge potential impact in the automotive engineering market.

Umpqua EVOPAC

The first is Umpqua Energy, based in Medford, Oregon, which has a technology licensed from Argonne National Laboratory which they are using to develop a system allowing a gasoline engine to operate in an extreme lean burn mode to increase mileage. Lean burn engines are usually plagued with high emissions because of the faster "flash" or burn rate and lower temperatures, which do not incinerate as many of the burn's byproducts. Using Umpqua's EVOPAC system, which combines advanced hydrogen-injection using a plasma reformer with a DeNOx Catalyst to increase the burn duration and temperature in lean burn operations.

The plasma reformer is installed into the engine compartment to convert some of the fuel being used into hydrogen (all petroleum-based and bio-based equivalent fuels have hydrogen in them) and then inject that hydrogen in with the fuel in the combustion chamber. The pure hydrogen burns faster and more efficiently, helping to incinerate the fuel more completely and adding more power to the stroke while keeping the benefits of a lean burn condition's (greater efficiency).

On the tailpipe, a DeNOx Catalyst, which removes the most harmful of gasoline's emissions, NOx or nitrogen - the leading cause of smog - by 85%. Tests on these technologies have shown reductions in fuel usage in H2-injection systems compared with conventional combustion with nearly-eliminated hydrocarbon and carbon monoxide emissions. The process requires refinement to be developed for market, which will be its next phase through the DOE.

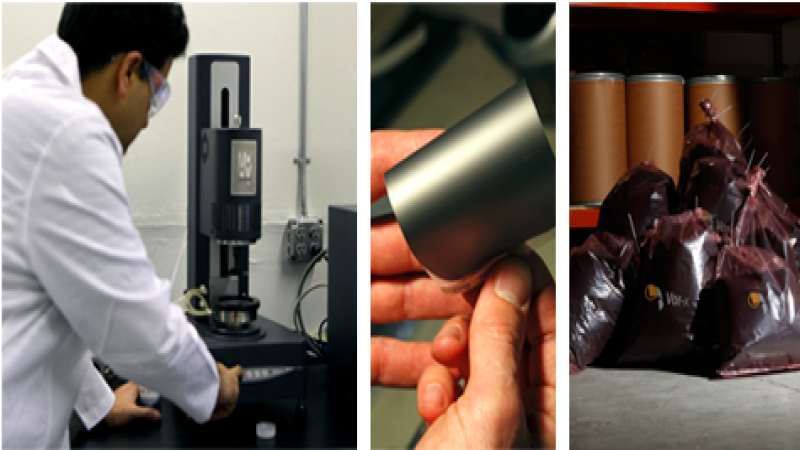

Vorbeck's Graphene for Lithium

The next is Vorbeck Materials in Jessup, Maryland who is working with Pacific Northwest National Laboratory with a method for better graphene development. LIthium-air and lithium-sulfur batteries are some of the latest burgeoning battery technologies for automotive and other uses. Vorbeck owns a license agreement from Princeton University for an Askay Labs method for graphene production at commercial scale. Combined with the PNNL process, the production method creates some of the highest energy storage capacity ever recorded. Through this DOE process, they hope to bring this technology to market rapidly for use in things large and small, including toys and commercial vehicles.

IPAT and Titanium Powder

Based in Nevada, Iowa, IPAT is working with the Ames Laboratory to make titanium powder with a process that is ten times more efficient than traditional powder-making methods. This would significantly lower the cost of titanium powder to manufacturers, increasing its options and useability. The powdered form of titanium is easier to work with than casting raw metal because of titanium's reactive nature.

Yet titanium's strength, light weight, and biocompatibility as well as its resistance to corrosion make sit an ideal material for many parts. If used more extensively because of this process' easier acquisition, titanium could be used in alloys for various automotive parts to significantly reduce weight while retaining or enhancing durability and strength. It could also be used in a myriad of other industries including medical, military, aerospace and more.

The U.S. DOE is now accepting applicants for the 2013 America's Next Top Energy Innovator competition.