The title of Dr. Oded Tour’s presentation per the DEER agenda will be as follows: Splitting the Cycle the Right Way: An Inherently Ultra-efficient, Low Emissions IC Engine.

For more than a decade, the DEER Conference has been the U.S. Department of Energy's (DOE's) primary mechanism for the public exchange of state-of-the-art advanced combustion engine research and development (R&D); and Tour Engine will be there with good reason, because every gallon saved in fuel consumption is a green event.

That is where I come in as correspondent for Torque News. Having covered engine technologies, I have been invited by Dr. Tour to meet with him for another private interview, but this time face to face.

Fact is, I have conversed with Dr. Tour about two or three times over the phone. Just recently he gave me three hours of his time with a presentation that often goes to venture capitalists, explaining in great detail the design and efficiencies of the Tour engine that bears the name of his father, Hugo Tour of Israel.

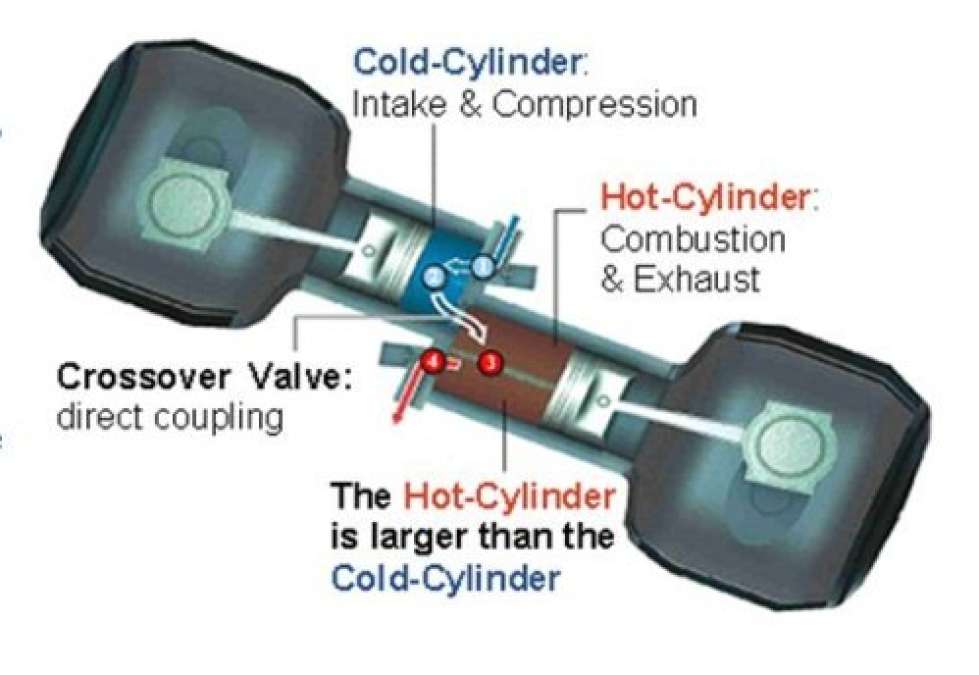

First, Tour Engine is both a company and a split cycle-cycle engine design that separates the cold side from the hot side. Furthermore, it has a unique arrangement as being the only split-cycle with opposed pistons; and there is a rational reason as to why - maximum thermal efficiency.

After I finished the 3-hour review of his design, it became clear to me that Tour intends to become the most thermally-efficient, internal-combustion engine on the planet; my words, not his. After all, it’s not everyday that I get a private tutor of the caliber of Dr. Tour.

And the plain truth is, present 4-cycle engines waste energy to a great degree, they resist green, and they have become extremely complex. As such, the Tour engine addresses the three is similar terms: efficient, green and simple.

In the words of Dr. Tour, “existing four-stroke engine designs are in conflict with optimization.”

I tend to agree as I have witnessed, as you have, the auto industry expending great amounts of time and money just to achieve incremental gains of 0.5% here, 1% at best there. Thus the industry has avoided doing what’s necessary, reconfiguring the IC engine so that those gains can be made much larger and achieved in one fell swoop.

At present, all engines use the traditional Otto Cycle or some variation like the Atkinson Cycle and Rankine Cycle, which attempt to achieve some level of efficiency of the Miller Effect. Coming up short, though, on maximizing thermal efficiency, all manufacturers end up making compromises between fuel efficiency, power and emissions. Thus, all use direct injection, turbo charging; others simply vie for variable cams and variable valve timing.

Problem is, the auto industry has approached a point where they will not be able to meet 2016 and 2025 MPG mandates unless a major change is made to increase thermal efficiency.

At present, existing engine designs allow extreme heat losses that could be used to do work, like propel the car. For example, 40% gets transferred to the radiator, another 30% goes out the tailpipe, and the remaining 30% is available to power the vehicle.

Tour is not the first to attempt a viable split cycle, though, to remedy the situation. Other designs have attempted to split the cycle, but most designs have crossover tubes which tend to reduce the ability to attain maximum thermal efficiency. And that’s where the Tour engine is different and excels. The Tour design, for example, adopts a single head approach with opposed pistons and dual crankshafts, whereby the valves allow for the best thermally efficient way to transfer air from the cold side to the hot side.

There are other engines with opposed piston variations, but they are still traditional Otto cycles or they are two-cycle diesels. None of those take advantage of the split cycle like the Tour engine.

For the record, the compressor or cold side of the split cycle engine works best when it is cold or thermally insulated from the hot power cylinder. And the Tour design makes every attempt not to deviate from that criteria. Retaining a hot cylinder allows for maximum power and more thorough burning of fuel. But it is the opposed piston-to-piston arrangement that makes the thermal efficiency of the Miller Effect possible.

There are certainly greater details about the valve designs, but I respect Dr. Tour’s request for non-disclosure of certain technical details. Likewise, I cannot disclose those companies that have signed non-disclosure agreements or plan to do so. However, I was pleased to see the interest in split-cycle engine technology is growing; more so than last year and the year before that.

In time, the Tour engine will be revealed like the others, but be apprised there is still a long way to go. For example, the beta prototype is scheduled to be built and tested either later this year or the beginning of 2012.

Question is, should a company like Tour Engine go for the automotive OEM applications right away or direct its efforts first toward smaller projects and ventures like generators, motorcycles, boats, etc.? Frankly, I would do both, but that requires venture capital which Tour is seeking.

From my own experience with design & build or start-ups and inventions, capital is crucial to achieve the next level of development, regardless of the project. After my own deep dive into the presentation by Dr. Tour, I dare say the team of Tour Engine has the credentials, and the design is worth a look by any venture capitalist, because the potential is there to meet the 2025 MPG mandates without having to change our present knowledge of high-volume manufacturing. And you can’t say that about vehicle electrification.

I look forward to speaking again with Dr. Tour at DEER.

More About DEER

For the record, Directions in Energy-Efficiency and Emissions Research (DEER) brings together professionals in the engine community including engineers, scientists, academics, State and regional regulators, environmental researchers and nonprofit organizations. At DEER 2011, DOE will showcase its cooperatively funded R&D with its partners, national laboratories, the Nation's automotive transportation industry, universities, and other national and international organizations.

DEER fosters the exchange of information and best practices through presentations and posters from new and on-going engine R&D and networking with industry colleagues. The exhibit hall features more than 50 companies showcasing the latest innovations, products, and services. Attendees will be able to get hands-on experience with new technology and speak with experts from the leading companies in the industry.

-----------------------

About the Reporter: After 39 years in the auto industry as a design engineer, Frank Sherosky now trades stocks, futures and writes articles, books and ebooks like, "Perfecting Corporate Character," "Awaken Your Speculator Mind", and "Millennial World Order" via authorfrank.com. He may be contacted here by email: [email protected] and followed in Twitter under @Authorfranks

________________________________________________

Additional Reading:

Tour Split-Cycle Engine technology display

Altair unveils world's first hydraulic-hybrid transit bus

Scuderi Split-Cycle Engine achieves 65 MPG under simulation study

Achates Power addresses commercial truck mileage and emission standards

Raytheon: Cyclone Power's combustion engine game changer

Buick LaCrosse with eAssist on par with highway fuel economy of compacts

Cella Energy achievement may make hydrogen fill-up a reality

Stop-start technology to advance more micro hybrids by 2016