How does Elon Musk manage to weave together innovation, performance, and affordability in this stunning piece of electric engineering? Let's roll up our sleeves and dive into the nuts and bolts of the cost analysis behind the Tesla Model Y.

Unpacking the Model Y's Production Puzzle

When you crack open the hood of the Tesla Model Y, you're not just peeking into a car - you're peering into the future of automotive manufacturing. The Model Y is built on Tesla's Gigafactories - massive production hubs designed to churn out EVs at a scale that'd make Detroit's head spin.

A critical component of the Model Y's affordability is Tesla's mastery of vertical integration. Traditional automakers often source their parts from various suppliers, leading to markups and supply chain complexities. But Tesla takes a different road. By producing a significant chunk of its parts in-house, the company sidesteps the middleman and slashes costs. It's like building a puzzle with your own pieces rather than buying a pre-made kit. As a result of Tesla's vertical integration, Tesla reduced the Model Y assembly to mere 2.5 hours.

Materials Matter: From Model Y's Batteries to Body

One of the most intriguing aspects of the Model Y's cost structure is Tesla's innovative use of materials, and that starts with the heart of every EV: the battery. Tesla's mastery of battery technology isn't just about performance; it's about affordability. The company has been steadily driving down the cost of battery production through advancements in cell design, chemistry, and manufacturing processes. This means more bang for your buck when it comes to range and longevity.

But the innovation doesn't stop there. Take a gander at the body of the Model Y. It's not your typical steel-and-iron behemoth. Tesla decided to go for something lighter and more space-age: a mix of aluminum and high-strength steel. This not only trims the fat, making the car more efficient, but it also simplifies production.

In the realm of EVs, every pound counts. A lighter vehicle means less strain on the battery, which translates to longer range and better performance. And with every mile you drive, you're getting more of that electron-pushing grin for your buck.

Tesla's Innovative Manufacturing: Robots and Efficiency

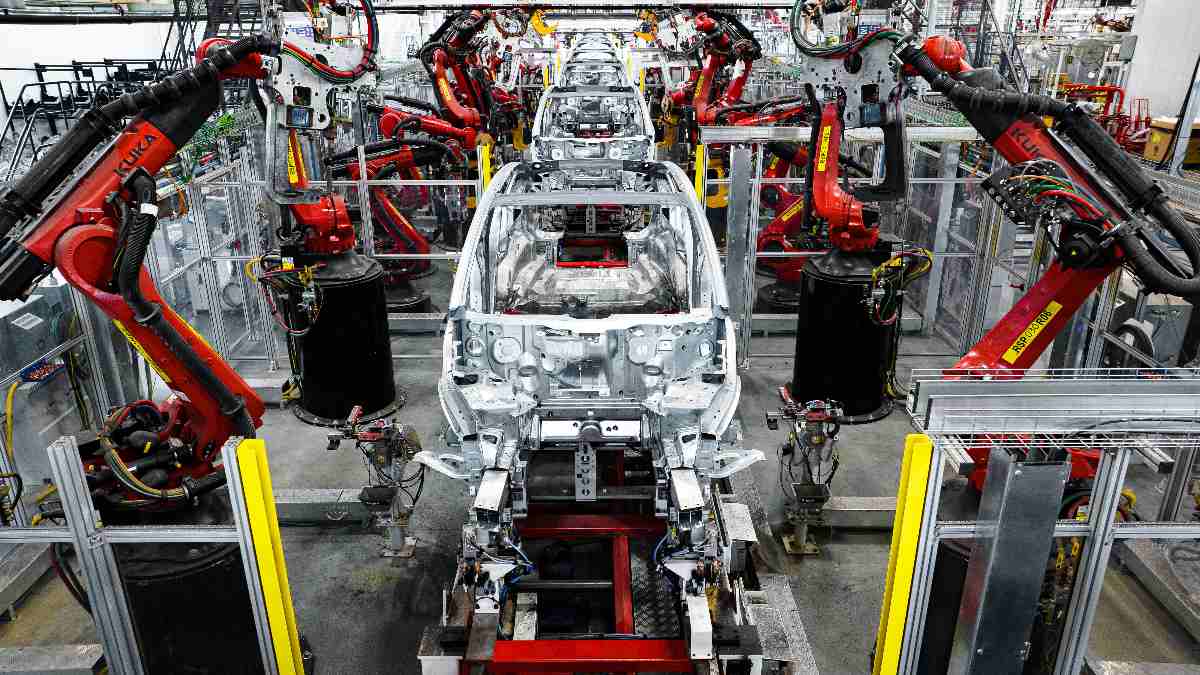

Imagine walking into a factory where robots are putting together the electric vehicle you want to buy. That's pretty much how the Tesla Model Y comes to life. Automation is one of the key cornerstones of Tesla's manufacturing process, allowing for precision and efficiency that human hands can't match.

Tesla's production lines are like choreographed dances of robots and machines, each performing their tasks with a grace that's both mesmerizing and cost-effective. From welding to assembly, automation ensures consistency, reduces errors, and speeds up the manufacturing process. And where traditional automakers might need dozens of laborers, Tesla needs just a handful of engineers to oversee the symphony of machines.

Model Y's Software: The Silent Cost Cutter

When it comes to the Model Y's affordability, it's not just about the physical components. The software that runs through the car's veins is equally important. Tesla isn't just an automaker; it's a tech company on wheels. And this technological prowess plays a significant role in keeping costs down.

The Model Y, like all Teslas, receives over-the-air (OTA) updates that improve performance, add features, and fix bugs. This means that instead of recalling vehicles for fixes or improvements, Tesla can simply send an update to your car. It's like your car getting smarter overnight.

But here's the cost-saving twist: these software updates can eliminate the need for physical changes or upgrades. Take, for instance, a software tweak that improves battery efficiency. Instead of needing to replace or upgrade a physical component, Tesla can achieve the same outcome through a few lines of code.

Economies of Scale: Beyond the Metal

When Tesla started its EV journey, skeptics often cited the high costs of producing electric vehicles as a roadblock. But Elon Musk and his team weren't driving with blinders on. They understood that as production scales up, costs go down - a principle known as economies of scale.

As Tesla's Gigafactories churn out more and more vehicles, they benefit from this principle. From sourcing materials in bulk to fine-tuning production processes based on accumulated experience, the Model Y's affordability is a testament to Tesla's ability to leverage its growing production volume to cut costs.

The Final Bolt: Balancing Innovation and Affordability

The Tesla Model Y isn't just a car; it's a testament to the power of innovation in the world of electric vehicles. While skeptics may scoff at the price tags of electric cars, the Model Y serves as a shining example of how innovation, vertical integration, cutting-edge materials, and streamlined production can lead to an affordable yet advanced electric SUV.

Elon Musk and his team have cracked the code of creating a vehicle that's not only thrilling to drive but also wallet-friendly. Through a symphony of software and hardware, they've managed to achieve the seemingly impossible: marrying innovation and affordability in a world where EVs were once deemed too expensive for the masses.

So, the next time you see a Tesla Model Y gliding silently down the road, remember that beneath its sleek exterior lies a masterpiece of engineering that's rewriting the rules of automotive cost structures. It's a reminder that the future of driving isn't just electric - it's efficient, innovative, and within reach for all of us.

What has been your experience with the Tesla Model Y? Please, share your opinion in the comments section below. Do you disagree with any of the points about the affordability of the Model Y discussed above?

Armen Hareyan is the founder and the Editor in Chief of Torque News. He founded TorqueNews.com in 2010, which since then has been publishing expert news and analysis about the automotive industry. He can be reached at Torque News Twitter, Facebok, Linkedin and Youtube.

Comments

Hi guys thanks for the great…

Permalink

Hi guys thanks for the great work. Please comment on Tesla's profit margins. Specifically, can you tell where the FSD gross revenue shows up in their accounting? I estimate 5% of the companies profits are coming from FSD sales. Please correct me if I am wrong. If so then it means their hardware margins are closer to industry norms.

Thanks!

Tim