It’s said that one has but mere seconds to make a positive first impression. For me, all it took was an initial glance through an opaque lobby door onto to the cleanest automotive production facility floor I’d ever encountered -- Honda’s Performance Manufacturing Center stood there before me.

Granted, the NSX rebirth has been a protracted one, with a bump or two encountered along the near-decade-long path of development of what is now the highest priced major manufacturer brand production car in North America. I only mention this factoid in recognition of a recent NPR piece penned on Honda’s latest Marysville, Ohio based production facility -- also its smallest automotive assembly plant. Developed on the racetrack, 2017 Acura NSX enters full production April 1, 2016.

Hands-on personal accountability with full transparency

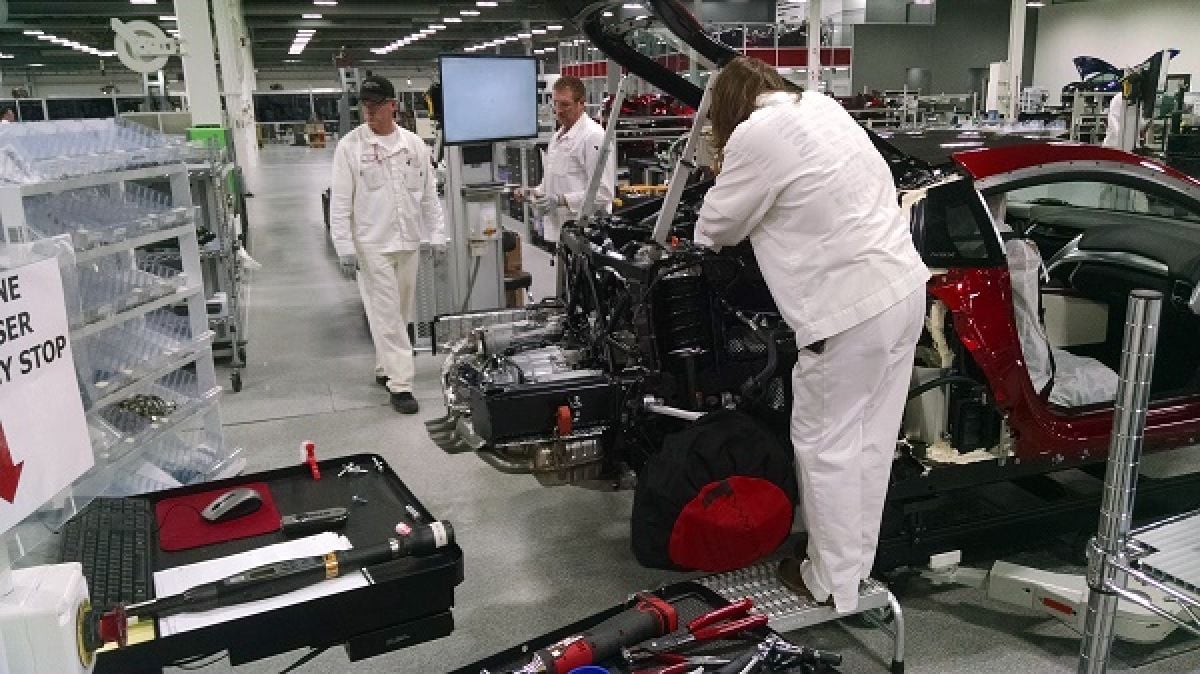

For this lifelong “gearhead,” dawning safety glasses and walking through Honda’s sparkling production facility is akin to a kid entering a candy store with unlimited access to his or her favorite treat. It’s a bit overwhelming at times -- a visual and auditory bombardment of state of the art glass-enclosed computer programed robotic welding rotating jigs -- remotely controlled robotic arm spray-nozzle downdraft paint booths -- and rubber-track trolley frame and body panel dip tanks -- the length of a football field; and all designed for safe public viewing.

Safety first Acura NSX style

Home to America’s designed and hand built hybrid electric supercar The PMC (performance manufacturing facility) facility is massive by “custom car” shop standards, with 180,000 square feet dedicated to 2017 NSX production and an additional 100,000 square feet or so earmarked for parts warehousing and finished vehicle docking and eventual transfer. Yet by automotive manufacturing standards, Honda’s newest facility dwarfs in comparison to the million square foot monsters producing 800 cars and light trucks per day.

Hand assembled, one torque measured bolt at a time

When Honda’s Performance Manufacturing Center hits peak production in April, a mere 8 Acura NSX supercars will drive off of the hand trolley moved production line per day. At the end of the day, Acura NSX is a mostly hand crafted and assembled, a segment breaking gasoline/electric hybrid supercar, produced by “master engine builders,” and Honda’s most competent, precision chassis, body and interior assembly craftsmen and women. As priced, ($156,000 to $212,000) 2017 Acura NSX is a relative supercar bargain.

At the heart of NSX lies an aluminum alloy and case hardened jewel

Each team member is held personally accountable to their assigned task -- one monitored coating and paint application, adhesive glued body panel, bead of seam sealer, electronic torque wrench tightened, and interior door or trim panel clip at a time.

To put the scope of NSX component assembly into perspective, one must view 2017 Acura NSX from the pre-automated-rotisserie-jig-welded frame component up --There’s a lot to the beast. Manufacturing NSX takes no less than 10 days in production for one Acura NSX supercar to make it to final dyno and rain-room weather testing.

Kid gloves insure fingerprint-free customer delivery

The car’s never touched with an ungloved hand, and is never exposed to outdoor elements and weather conditions prior to dealership delivery. And that’s done in a climate controlled enclosed car carrier. We encountered our first 2017 Acura NSX in Los Angeles.

2017 Acura NSX is aluminum alloy intensive, with a twist.

2017 Acura NSX Supercar is Acura’s most technically advanced undertaking to date. It’s the only mega-auto-manufacturer produced supercar in the United States. And at its core, is essentially hand assembled by a dedicated international team of 100 men and women, in a facility no larger than a Costco or Home Depot outlet. You will discover full 2017 Acura NSX specifications here.

One could literally eat off of the floor

With a capital investment of $70,000,000, Honda converted a parts storage and distribution center into the showcase that is the Marysville, Ohio Performance Manufacturing Center -- home to Honda’s greatest engineering challenge(second only to the Honda Jet) to date. And it is by all accounts magnificent!

Photo and video attributions Parks McCants for Torque News 2016