Ford Motors is taking a fairly holistic approach to what some call "sustainable transportation," not only is the company developing a comprehensive range of electrified vehicles, but Ford's researchers are looking into biomaterials to replace the traditional fossil fuel based plastics and foams. Ford and Weyerhaeuser just announced a research project looking at using tree fibers to make plastic composites that can be used in automobile interiors.

Traditionally the source materials for vehicle interiors have been fiberglass, minerals and/or petroleum. Extracting and processing these materials cause an environmental footprint as well as being a part of the whole fossil fuel dependency story. Replacing these materials with biomaterials means being able to grow the source materials, rather than source them from extractive mining practices. As a general principle, extractive mining is a "use once and throw away" pattern that is a recipe for eventual society collapse because of running out of resources. Growing resources and materials is the opposite of "use once and throw away" because we can always grow more plants.

“Our responsibility to the customer is to increase our use of more sustainable materials in the right applications that benefit both the environment and product performance,” said John Viera, Ford global director of Sustainability and Environmental matters.

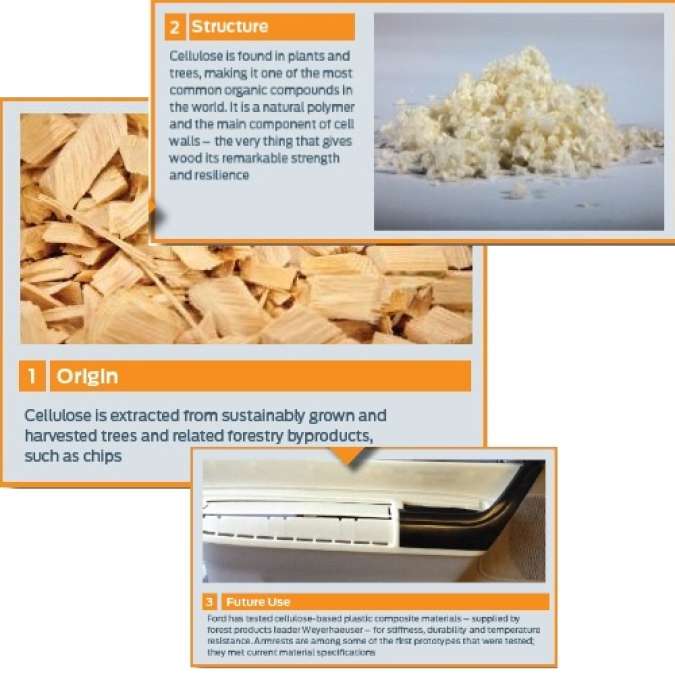

About three years ago Ford and Weyerhaeuser began research into cellulose-based plastic composite material for potential use in vehicle components. Prototype vehicle components were created and put through a battery of tests by a team led by Dr. Ellen Lee, Ford’s plastic research technical expert. “We found that working collaboratively at an early stage has accelerated the development of a material that has a high thermal stability, doesn’t discolor and doesn’t have an odor,” said Lee. “That’s important because it opens the door for use of the material in a wide range of applications that could eventually add up to significant environmental benefits across our product line.”

They've found that not only can biomaterials be used for vehicle interiors, but it's a good candidate for exterior and under-the-hood components as well.

Weyerhaeuser's role is that the company over 20 million acres of forest land, and the company claims its forest management practices are sustainable. “Weyerhaeuser is a pioneer in sustainable forestry. Last year, for example, we planted more than 66 million seedlings as part of an ongoing process of renewal that ensures forests and the products that come from them meet present and future needs,” said Don Atkinson, vice president market development and new products for Weyerhaeuser’s Cellulose Fibers business.

All this sounds nice and groovy, but there is another side to it. This is part of a general trend towards treating the natural world as if it is a factory for growing any kind of industrial material.

Earlier this month Ford presented marketing research that a "green attitude shift" among consumers justifies efforts of this sort.